专注于SF6气体检测的专业化

SF6 gas density micro-water on-line monitoring scheme

Sulfur hexafluoride (SF6) is a non-toxic, tasteless, colorless, odorless, non-combustible synthetic gas, with general dielectric incomparable insulation characteristics and arc extinguishing ability, widely used in the power industry in high-voltage circuit breakers and substation equipment, almost become high voltage, ultra-high voltage circuit breakers and GIS in the insulation and arc extinguishing medium.

The two physical indicators of SF6 gas density and humidity can represent the insulation and arc extinguishing performance of SF6 gas, so the operation regulations of the National Power Company stipulate that the density and humidity of SF6 gas must be regularly tested before and during the operation of the equipment.

1. When SF6 gas moisture content is high, it is easy to condense on the insulating material, resulting in decreased insulation performance, and in serious cases, flashover breakdown occurs. The acidic substances generated under the action of arc are highly corrosive, which has a strong corrosion effect on solid organic materials and metals, shortening the life of the equipment.

2, the high water content of the gas under the action of the arc produced compounds affect the purity of SF6 gas, arc extinguishing ability will be affected.

3. The gas with high water content generates toxic and harmful substances under the action of arc, which directly endangers human health.

Pure sulfur hexafluoride gas is a colorless, odorless, non-toxic, chemically stable, will not burn gas, in electrical properties with good insulation performance, no fire danger, good arc extinguishing performance and many other advantages. Therefore, with the rapid development of the power industry, the circuit breaker and GIS equipment with SF6 gas as the arc extinguishing medium have been widely used. However, if the water content of SF6 gas is too much, it will harm the operation of the equipment. Therefore, the water content of SF6 gas must be strictly controlled to provide reliable information and basis for the maintenance of the state of the power system and the construction of the smart grid, and ensure safe production.

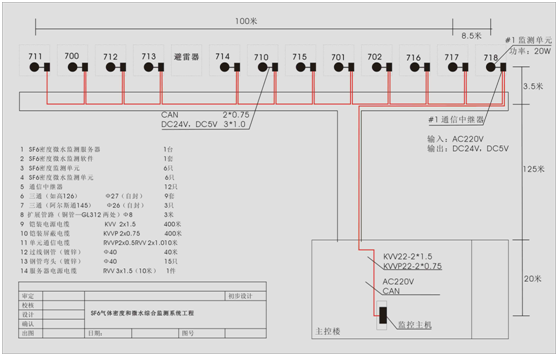

Advantages: 1, real-time data acquisition (humidity, density, temperature), data remote transmission, fault alarm, background analysis, historical query. 2, the system automatic cycle diagnosis function (self-diagnosis function). 3, sensor self-calibration function (self-calibration function). 4, automatic heating function (self-cleaning function), calculate and convert the moisture and density parameters under 20℃ standard conditions. 5, hand in hand communication connection device, and can achieve a variety of data acquisition methods (wired + wireless). 6, the product equipment is stable, reliable operation, unique sealing structure design packaging fastening, fully waterproof, anti-fouling, dust, highly integrated small size, light weight, military standards.

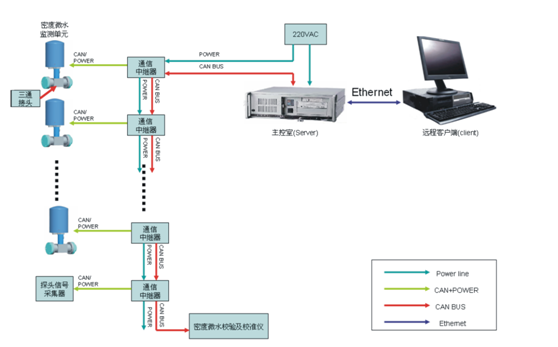

SF6 Micro-water density online monitoring system (Winfoss-S6) allows users to access and understand the operating status of each substation more conveniently, anytime and anywhere. Maintenance personnel can clearly know what they need and how to do it. At the heart of all this technology is the DRYCAP® based micro-water measurement analysis algorithm and the digital SF6 gas density monitoring technology. The expert diagnosis system is formed by combining digital processing technology (DSP) and real-time database technology. It ensures that the change of dynamic digital pressure and micro-water monitoring data can accurately reflect the deterioration trend of gas quality inside the switch, and provide a scientific basis for users to provide state preventive maintenance.

SF6 Micro-water density online monitoring system (Winfoss-S6) can realize the online collection, data processing and data output of SF6 gas temperature, pressure, density and micro-water. The background system can be used to collect the temperature, pressure, density and water content of the gas online in real time, and automatically alarm according to the set alarm and locking limits. At the same time, the saved operating information can also be applied to calculate the leakage rate of the gas inside the equipment, providing reference data for users to regularly detect the equipment, reducing the number and time of power outages, and obtaining greater economic benefits.

Function description:

1, integrated mechanical dial display SF6 gas density value and contact output and SF6 gas temperature, pressure, density and water content of digital signal output, to achieve mechatronics design.

2. Build a remote transmission density relay remote communication network to collect and process data of SF6 gas density, pressure, temperature and water content.

3, integrated online monitoring system software to achieve real-time display of SF6 gas temperature, gas pressure (density), water content and other information in SF6 electrical equipment, and can be judged according to the set alarm value, when the gas leakage in the equipment can be issued in time.

4, Build online monitoring system hardware network platform. The central server of the platform has the function of disk array, so as to ensure the reliable operation of the system and have recoverability.

User benefits:

The device realizes real-time on-line monitoring of SF6 gas density, temperature, pressure and water content in the whole station. The water content and SF6 gas temperature, pressure and density integrated acquisition device can upload the monitoring amount of each monitoring point to the background system by means of data bus networking. Realize online alarm of gas density reduction, warning of excessive water content, automatic data saving and historical curve generation, and automatic data report generation. It can reduce the workload of personnel inspection and meter reading, realize fault early warning, provide reference data for users to regularly detect equipment, reduce the number and time of power outage, and obtain large economic benefits.

EN

EN

上一条:

上一条:

沪公网安备31011802003762

沪公网安备31011802003762