专注于SF6气体检测的专业化

What are the hidden dangers when using sulfur hexafluoride (SF6) switches?

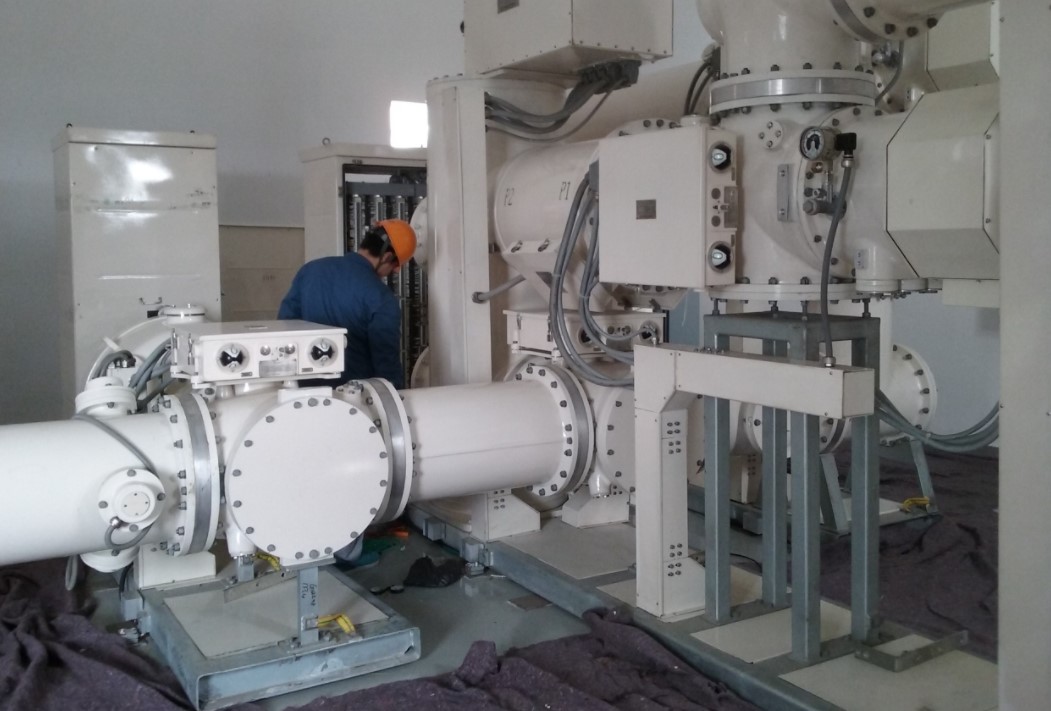

Sulfur hexafluoride gas has excellent insulation and arc extinguishing properties, and is called "century gas". Its emergence has caused a very far-reaching innovation in high voltage switchgear. Because sulfur hexafluoride gas has excellent insulation and arc extinguishing performance, it is widely used in today's transmission and distribution switchgear above 110kv and 24kv~36kv generator protection circuit breakers. In the distribution switchgear above 35kv, the electrical industry departments in some large cities and regions should use sulfur hexafluoride circuit breakers to replace other circuit breakers. The development and application of sulfur hexafluoride gas insulated switch combination electrical equipment with miniaturization, lightweight, less (free) maintenance and intelligence in 3.6kv~27.5kv distribution switchgear is becoming more and more extensive. As far as the world market is concerned, Europe and most Middle Eastern countries are biased towards SF6 switches.

The reason why sulfur hexafluoride has a strong arc extinguishing ability is mainly because:

one Sulfur hexafluoride gas forms a plasma composed of sulfur, fluorine atoms, positive and negative ions and electrons at high temperature, and the plasma has a high temperature at the arc temperature, so the same current, the arc voltage is low, the heat generated in the arc gap is less, and the smaller arc blowing speed can make the arc get enough cooling.

2. The temperature characteristics of the conductivity and specific heat capacity of sulfur hexafluoride are relatively special. When the arc temperature reaches a certain value, the heat absorption effect becomes larger, and the thermal conductivity also increases, which has a strong cooling effect on the arc, so the arc becomes finer in sulfur hexafluoride. Because the arc column is thin and contains less heat, the dielectric recovery rate of the arc gap rises faster, so the sulfur hexafluoride switch device can withstand a high recovery voltage rise rate.

3. Sulfur hexafluoride is very electronegative. Sulfur hexafluoride molecules are easy to capture free electrons and form negative ions. The mobility of heavy negative ions is low, which makes the development of electron collapse difficult, thus weakening the development process of discharge and improving the rising speed of medium recovery.

In addition, the contacts sealed in sulfur hexafluoride will not oxidize, and the contact resistance can remain stable; At the same time, it is not necessary to use the general contact pressure to wipe the oxide film, thus reducing the wear of the contact. In addition, in sulfur hexafluoride, the interception before the current crossing zero is small, and thus excessive interception overvoltage is avoided.

Pure sulfur hexafluoride itself is non-toxic, and experiments have shown that there are no adverse effects when present up to 80% sulfur hexafluoride and 20% oxygen. Therefore, when the atmosphere contains a high proportion of sulfur hexafluoride, the maximum concentration is set at 1000ppmv (600mg/m3) for places where staff work 8 hours a day, 5 days a week.

Compared with sulfur hexafluoride switch, vacuum switch is mainly manifested in the following aspects:

one The vacuum degree of the vacuum switch can not be monitored: in actual operation, the vacuum degree as an arc extinguishing medium is a key indicator to determine whether it can be put into operation and whether it can be divided and closed during operation. However, in actual operation, the operator can not monitor the vacuum degree. Sulfur hexafluoride switches, however, can be used in a variety of ways to detect air pressure and can be electrically or mechanically interlocked.

2. The contact of the vacuum switch must be replaced if it is worn to a certain extent. The sulfur hexafluoride switch contacts wear less, do not need to consider its excessive wear caused by the performance reduction.

3. The vacuum switch has a small opening distance, higher performance requirements for the operating mechanism (to ensure speed, but also to reduce the bounce), requires better control of the contact overrange and contact pressure, and requires high precision with the arc extinguishing chamber and the operating mechanism. The sulfur hexafluoride switch contact opening distance is generally relatively large, the operating mechanism performance is simple and reliable, and the use of maintenance-free period is long.

4. Because the vacuum switch breaks a small current, especially when the no-load transformer excitation current and other small inductive current, there will often be interception and interception overvoltage, and the larger the interception value, the higher the overvoltage. In addition, when the vacuum circuit breaker opens the capacitive current of the power supply container group, it is also difficult to achieve absolutely no arc reignition, and once there is reignition, it will also produce reignition overvoltage. Shutdown overvoltage and reignition overvoltage do great harm to the whole system and the switch itself. The sulfur hexafluoride switch does not produce closure due to its excellent electrical properties.

5. At present, the domestic 10kv class (dry) vacuum series products have not been tested by harsh operating environmental conditions such as damp, heat and pollution, and their performance in high altitude, heavy pollution, salt spray and other environments must be studied. The sulfur hexafluoride switch has the advantages of simple structure, strong arc extinguishing and insulation performance, small operating power, high rated parameters, long electrical life and no maintenance cycle, and is less affected by external climate conditions, which is very suitable for outdoor use.

The excellent performance of sulfur hexafluoride switches is obvious, so it has been widely used in the field of power. The application of sulfur hexafluoride switches in foreign countries (such as Germany, Finland, etc.) generally accounts for 80% to 90% of the total market, and the application of sulfur hexafluoride switches in China is also rising year by year, accounting for 10% to 20% of the total market, but it is too far away from foreign countries, and the reasons are mainly analyzed as follows:

one The application and promotion of the early vacuum switch in the oil-free transformation is faster, the vacuum technology is relatively skilled, and customers are more aware of the operation and maintenance requirements of the vacuum switch, so they are more inclined to use vacuum.

2. The sulfur hexafluoride switch attracted great attention in the 1990s, and achieved rapid development, and it took some time for customers to accept this technology.

3. The sealing of some domestic sulfur hexafluoride switch manufacturers is not good, and there is a failure in the application, leaving customers with concerns at the beginning. With the rapid development of sulfur hexafluoride switch technology, and the use of advanced cutting and welding equipment, the seal of the switch has been greatly improved, sulfur hexafluoride switch can generally be made more than 10 years of maintenance free guarantee, foreign manufacturers can guarantee to 30 years.

EN

EN

上一条:

上一条:

沪公网安备31011802003762

沪公网安备31011802003762