专注于SF6气体检测的专业化

What is SF6 infrared spectrum?

When a beam of infrared light with a continuous wavelength is irradiated on a substance, if the vibration frequency of a group in the substance molecule is the same as the frequency of light, the two will resonate, that is, the group absorbs the infrared light at this frequency; On the other hand, matter does not absorb light energy. The light through the material through the monochromator dispersion, its frequency is expressed by wave number or wavelength, its transmission degree is expressed by transmittance, so that one by one record the intensity of each wavelength of transmitted light, you get the infrared spectrum of the material, simply put, infrared spectrum is to record the material of infrared light transmission degree and wavelength relationship diagram.

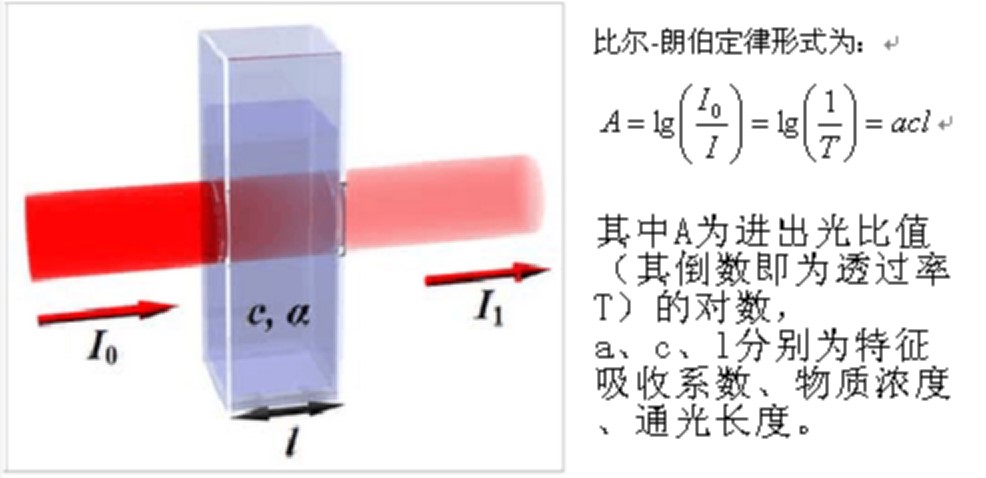

non-dispersive infrared absorption (NDIR) is a spectroscopic gas detection method based on gas absorption theory. Its performance is: After the infrared radiation emitted by the infrared light source is absorbed by a certain concentration of the gas to be measured, a specific wavelength (SF6 corresponds to 10.6um), when the light intensity will change corresponding to the gas concentration, and the change law can be described by Beer-Lambert absorption law. Therefore, the gas concentration can be calculated according to the change of light intensity.

In the field of SF6 gas leakage monitoring, the advantages of infrared monitoring technology have gradually been recognized and paid attention to. NDIR infrared gas detection technology has the advantages of high sensitivity, high precision, high stability and reliability, and long life. Because each leakage point is equipped with an SF6 infrared sensor and an oxygen sensor, the sampling at each point is independent of each other, and both are in-situ direct contact analog acquisition and digital conversion after sampling and analysis. There is no secondary sampling and analysis chamber in the pumping architecture, and the detection accuracy is not affected by the mixing of residual gas in the pipeline and analysis chamber.

EN

EN

上一条:

上一条:

沪公网安备31011802003762

沪公网安备31011802003762