专注于SF6气体检测的专业化

What is the working principle of SF6 gas infrared sensor?

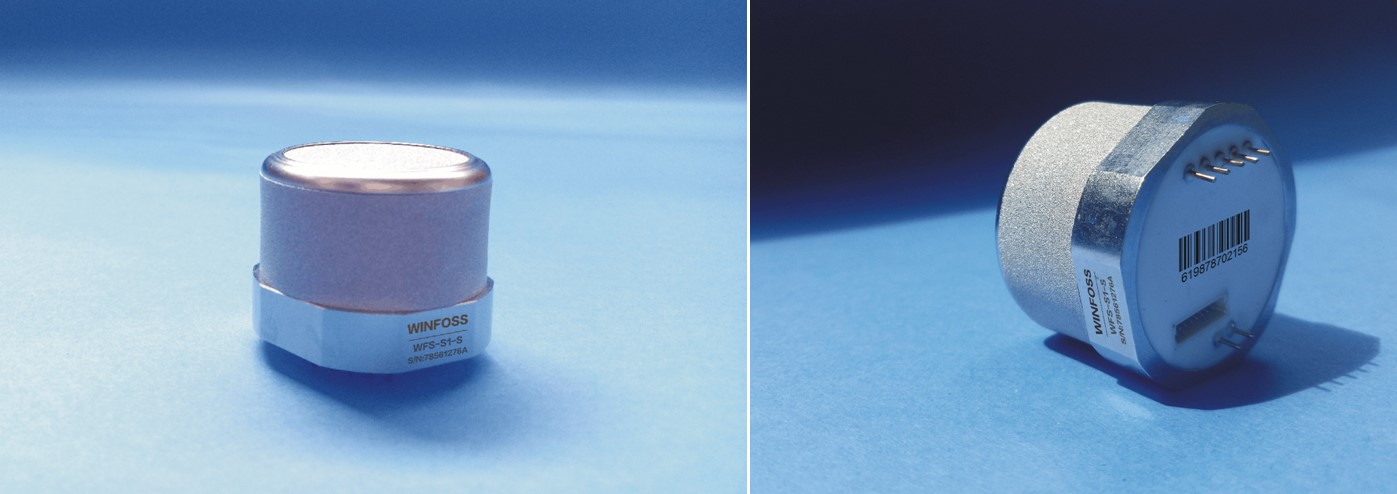

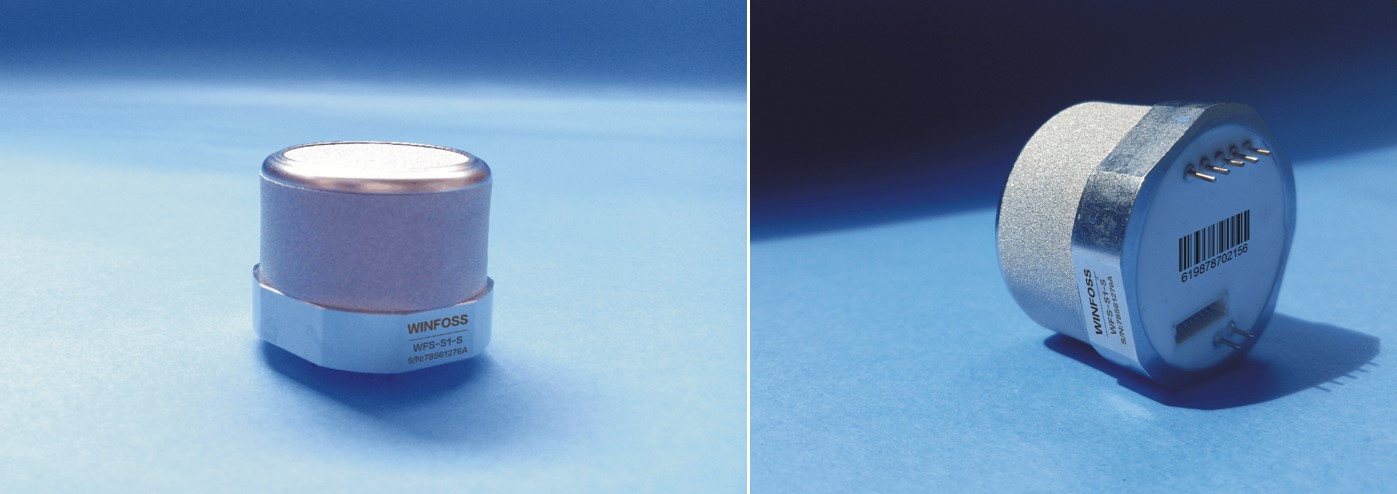

SF6 infrared sensor (WFS-S1-S) based on dual-beam dual-wavelength infrared measurement technology and high-precision digital processing technology, is widely used in high voltage switch GIS room SF6 gas leakage monitoring (0-100ppm). Sulfur hexafluoride SF6 gas leak detector (0-50ppm) and SF6 purity analyzer (0-100%). Internal integration of complete drift control circuit and temperature compensation circuit. SF6 Infrared gas sensor (WFS-S1-S)SF6 gas sensor adopts dual beam non-spectral infrared (NDIR) detection technology, has the advantages of anti-interference of other gases, easy maintenance, good stability, temperature compensation, Modbus ASCII protocol, digital output and analog output. Suitable for leakage alarm, on-site construction protection, simple gas analysis gas, online monitoring, industrial process analysis and other occasions.

non-dispersive infrared absorption (NDIR) is an optical gas detection method based on gas absorption theory. After the infrared radiation emitted by the infrared light source is absorbed by a certain concentration of gas to be measured, the intensity of the light at a specific wavelength will change in relation to the concentration of the gas, which can be described by the Bier-Lambert absorption law. Therefore, the gas concentration can be calculated according to the change of light intensity.

The unique light-free cell NDIR technology is equipped with a highly breathable stainless steel housing and can be connected to an external oxygen sensor with a digital signal output. Because it is designed for SF6 specific wavelength, it is resistant to other gas interference, does not require air pump pipeline, small size, strong corrosion resistant shell, easy to use and maintain, can upload and output sulfur hexafluoride content and oxygen content at the same time, and is suitable for leak alarm, environmental detection, online monitoring, gas composition analysis and other applications.

The SF6 infrared sensor (WFS-S1-S) developed and produced by WINFOSS is based on the principle of infrared spectroscopy, that is, the principle of infrared laser. The principle is that SF6, as a greenhouse inert gas, has a strong absorption characteristic for specific bands of infrared light, high sensitivity, is not affected by the environment and interference, no other gas interference, and the detection error caused by changes in the temperature and humidity of the environment is small, will not produce false alarms, infrared SF6 sensor life of up to 10 years. Because it adopts the principle of active extraction of gas at the test point, the effect is that the leak is found early and the reaction is rapid.

At the same time, the system structure also brings great convenience to the wiring in the project implementation. People often think that infrared spectroscopy technology is high cost, in fact, with the development of light detection technology, the price of infrared SF6 sensor has been greatly reduced, currently only need RMB4500 yuan a. At present, the main manufacturer of this principle is the SF6 infrared sensor (WFS-S1-S) produced by WINFOSS company in Switzerland, digital output, easy networking between sensors, due to the moderate price, 10 years of life, many domestic SF6 monitoring and alarm systems are using Wevers manufacturers of infrared sensors.

Advantages of the infrared SF6 sensor compared to the principles of electrochemistry and negative corona discharge:

1. Infrared Spectrum Absorption Principle (NDIR).

2. Dual wavelength, with temperature compensation.

3. High reliability, no cross reaction with other gases.

4. Compared with the electrochemical sensor, the infrared sensor of sulfur hexafluoride sensor has a life of up to 10 years.

5. High cost performance, affordable preferential price.

6. Compared with electrochemical sensors, sulfur hexafluoride sensors save after-sales maintenance costs.

7. Digital and analog output mode is optional, convenient for secondary development and application.

8. Micro structure, low power consumption design.

9. No radiation source, no secondary hazards.

Compared with the thermal conductivity principle, the SF6 infrared sensor (WFS-S1-S) has the advantages of:

1. Infrared SF6 purity sensor is small in size.

2. Infrared SF6 purity sensor Low power consumption, battery powered.

3. The infrared SF6 purity sensor does not require a large heating system.

4. Infrared SF6 purity sensor operating temperature wide (-20-+60°C).

5. More than 3 years of calibration cycle, no need to check the instrument frequently.

6. High reliability and stability, no daily maintenance of SF6 purity analyzer.

EN

EN

上一条:

上一条:

沪公网安备31011802003762

沪公网安备31011802003762