专注于SF6气体检测的专业化

Working principle of single and double pressure SF6 circuit breakers

SF6 circuit breaker is mainly composed of working cylinder, main voltage reservoir, arc extinguishing chamber, voltage equalizing capacitor, triple header, pillar, connecting seat, density relay, oil supply and discharge valve and auxiliary fuel tank, which is a closed combination electrical appliance. SF6 gas mainly plays the role of insulation, arc extinguishing and heat dissipation, chemical properties are very stable, is a colorless, odorless, non-toxic, will not burn gas. The action process of SF6 circuit breaker is like this: After the piston in the working cylinder is subjected to the pressure from the oil valve, the insulation rod in the drive pillar moves up and down, and after the connecting rod mechanism in the three-box is changed, the pressure cylinder, active contact and arc contact in the arc extinguishing chamber move accordingly, so as to realize the closing and opening. Its arc extinguishing structure generally adopts single pressure variable open distance double blowing type.

The arc-extinguishing principle of the circuit breaker is as follows: When the brake is opened, the moving part compresses SF6 gas in the pressure chamber and increases the pressure, so that the active contact and the main static contact are separated first, and the current is transferred to the arc moving contact and the arc static contact. When the arc extinguishing contact is separated, the high-pressure SF6 gas in the pressure chamber blows into the arc through the nozzle, and the gas is divided into two ways at the nozzle exit, one way to the static contact and the other to the moving contact. A bidirectional arc blowing that forms a high-speed airflow and extinguishes the arc when the current crosses zero.

SF6 circuit breaker interrupter chamber structure according to the pressure of the interrupter medium is different, divided into double pressure type and single pressure type, but the double pressure type is generally not used because of the complex structure and auxiliary equipment. According to the direction of the blowing arc, it can be divided into double blowing, single blowing, external blowing and internal blowing. According to the direction of movement of the contact, it is divided into fixed quenching distance (also known as fixed opening distance) and variable quenching distance (also known as variable opening distance). In addition, on behalf of the development and research of self-energetic arc extinguishing chamber.

The so-called single pressure SF6 circuit breaker refers to the SF6 gas only has a low pressure in the circuit breaker, the moving part of the arc extinguishing chamber has a pressure device, by the relative movement of the piston and the cylinder in the process of opening, like the air cylinder pumping, so that the gas pressure rises rapidly in a short time, forming a high pressure gas blowing arc, so that it is extinguished. The speed of the moving contact determines the size of the blowing volume. Once the opening operation is completed, the pressure effect disappears immediately and the low pressure gas is restored between the contacts. When the brake is opened, due to the role of the pressure cylinder, the gas pressure can be increased by 1 to 2 times than the original. The single pressure type arc extinguishing chamber is also called the compressed air type arc extinguishing chamber because of the compressed air device. Compared with the double pressure SF6 circuit breaker, the single pressure SF6 circuit breaker has the advantages of simple structure, no heating and low cost.

The single pressure interrupter is divided into two categories: variable opening distance and fixed opening distance.

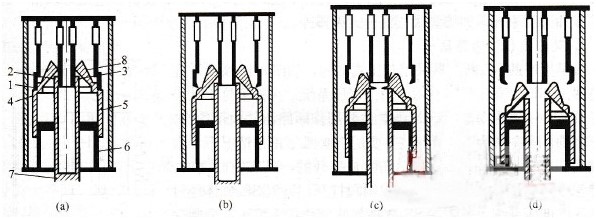

(1) Variable open distance single pressure interrupter. The contact of the variable opening distance single pressure interrupter is composed of the main circuit working contact and the arc contact. The working contact is placed on the outside to improve the heat dissipation conditions and improve the thermal stability of the circuit breaker. The moving part of the interrupter is composed of a moving contact, a nozzle and a pressure cylinder. Figure 2-19 shows the working principle of the variable opening distance single pressure interrupter. Figure 2-19(a) shows the contact in the closing position. When the brake is opened, the compressed air piston is fixed, and the operating mechanism makes the dynamic arc contact, arc extinguishing nozzle and pressure cylinder move through the pull rod to generate pressure between the compressed air piston and pressure cylinder. At this time, no arc has been formed and the arc extinguishing nozzle has not been opened, as shown in Figure 2-19 (b). After the dynamic and static arc contacts are separated, an arc is generated between the two contacts. As the dynamic arc contacts and the moving system continue to move downward, SF6 gas in the pressure cylinder continues to be compressed on the one hand, while the high-pressure gas is blown to the elongated arc through the opened arc extinguishing nozzle, and is extinguished when the current passes zero, as shown in Figure 2-19 (c). Figure 2-19 (d) shows the contact in the opening position after the arc is extinguished. Because the opening distance of the contact is changed in the arc extinguishing process, it is called the variable opening distance single pressure arc extinguishing chamber.

Figure 2-19 Working principle of the variable open distance single pressure interrupter

(a) The contact is in the closing position; (b) Pneumatic processes; (c) arc-blowing conditions; (d) The contact is in the opening position

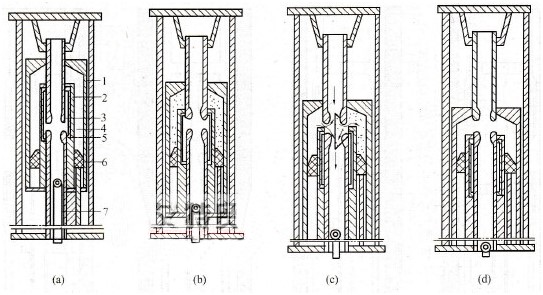

1- Main static contact; 2- static arc contact; 3- moving arc contact; 4- Active contact; 5- pressure cylinder; 6- pressure air piston; 7- Pull rod; 8- Arc extinguishing nozzle (2) Fixed distance single pressure arc extinguishing chamber. The contact of the single pressure type arc extinguishing chamber is composed of two empty static contacts with nozzles and moving contacts, and the arc gap of the circuit breaker is maintained by two static contacts with a fixed opening distance, so it is called the fixed opening distance structure. Figure 2-20 shows the working principle of the fixed-distance single-pressure interrupter. Figure 2-20 (a) shows the situation when the contacts are in the closing position. The moving contacts are connected between the static contacts 3 and 5 to form a current loop. When the brake is opened, the compressed air piston is fixed, and the operating mechanism moves through the tie rod with the moving contact and the pressure cylinder. SF6 gas in the compressed air chamber is compressed, and a high air pressure is established between the compressed air piston and the pressure cylinder, as shown in Figure 2-20 (b). When the moving contact is removed from the static contact, an arc is generated. At the same time, the pressure chamber closed by the moving contact is opened and high-speed air is generated, and the arc is blown lengthways, as shown in Figure 2-20 (c). When the arc is extinguished due to blowing and cooling, the contact is in the opening position as shown in Figure 2-20 (d).

The comparison of variable opening distance and fixed opening distance interrupter is as follows:

(1) Fracture condition. The electric field distribution between the interrupts in the variable opening distance is poor, the opening distance of the contacts increases continuously during the opening process, and the final opening distance ratio is large, and the fracture voltage can be increased higher. The electric field between the breaks of the arc extinguishing chamber is more uniform, the insulation performance is more stable, and the contact opening distance is short.

(2) Breaking ability. The arc of the variable opening distance interrupter is drawn longer and the arc energy is larger, which is not conducive to the improvement of the interrupter and breaking current. The arc of the constant opening distance interrupter is short and the length is fixed, the arc energy is small, so the arc extinguishing ability is strong, the arc burning time is short, and the breaking current is large.

Figure 2-20 Working principle of a fixed-distance single-pressure interrupter

(a) The contact is in the closing position; (b) Pneumatic processes; (c) arc-blowing conditions; (d) The contact is in the opening position

1- pressure cylinder; 2- Moving contact; 3, 5- static contact; 4- Pressure chamber; 6- Piston; 7- Insulation rod

(3) Air blowing condition. The gas blowing time of the variable open distance arc extinguishing chamber is relatively rich, and the gas utilization in the pressure cylinder is relatively full. The arc blowing time of the fixed opening distance arc extinguishing chamber is short, and the gas utilization in the pressure cylinder is slightly poor.

Single-voltage interrupter has the advantages of simple structure, low cost and good performance. It is mostly used in 110kV and above high-voltage power grids, and the breaking current can reach dozens of kilomanths. For the time being. The rated breaking current of the single voltage SF6 circuit breaker has reached 80kA, and the voltage of the single break has also been increased from the early 126kV to 550kV.

EN

EN

上一条:

上一条:

沪公网安备31011802003762

沪公网安备31011802003762