专注于SF6气体检测的专业化

What are the functional features of SF6 micro-water density online monitoring system?

Functional characteristics and technical indexes of SF6 micro-water density on-line monitoring system

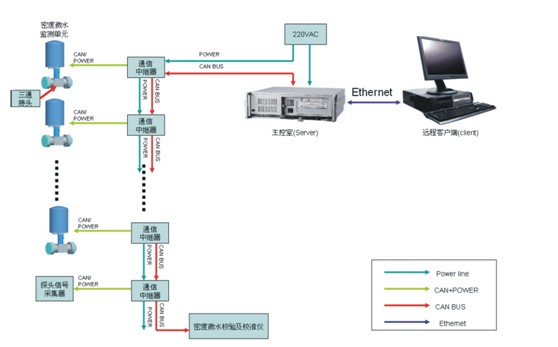

SF6 Density micro-water online monitoring system (Winfoss-S6) adopts high-performance micro-water sensor and density sensor with temperature compensation function. The collected data CAN be connected to substation integrated automation system and remote monitoring center through RS-485 or CAN bus. Long-term condition monitoring of SF6 circuit breaker to ensure the safe and stable operation of power equipment, and make the condition maintenance can be realized.

SF6 density micro-water online monitoring system is more convenient to use, anytime and anywhere to access and understand the operating status of each substation. Maintenance personnel can clearly know what they need and how to do it. At the heart of all this technology is the DRYCAP® based micro-water measurement analysis algorithm and the digital SF6 gas density monitoring technology. The expert diagnosis system is formed by combining digital processing technology (DSP) and real-time database technology. It ensures that the change of dynamic digital pressure and micro-water monitoring data can accurately reflect the deterioration trend of gas quality inside the switch, and provide a scientific basis for users to provide state preventive maintenance.

Main functions and characteristics

Realize the online monitoring function of SF6 gas moisture and density in the detected gas chamber, and display the monitoring unit number, standard pressure (20℃), moisture value (ppm), current pressure, current temperature, dew point value, density alarm value and lock value on the server.

1) High precision and reliability

The transmitter adopts the imported high stability sensor, the sensor is corrected and compensated by the internal circuit of the transmitter, and the output linearity is good and the precision is high. The external structure of the transmitter is also more suitable for measurement in high-frequency electric field environment, and it is integrated with the circuit processing part to reduce interference coupling and improve the long-term stability and reliability of the circuit.

2) To achieve online monitoring and status maintenance

The monitor can operate on line for a long time. It is equipped with RS-485/CAN communication interface, monitoring data can be uploaded to the monitoring center in real time. When the measured gas index exceeds the standard, the monitor will automatically upload the alarm or lock signal to the remote monitoring center according to the preset threshold, or directly start the alarm or lock device. The upper computer software can sample and store the monitoring data according to the set time and frequency, and automatically draw the above data into the trend chart for observation and analysis.

The application of SF6 gas integrated online monitoring technology can realize the status monitoring of the circuit breaker, which is conducive to timely grasp the operating status of the equipment, ensure the safe and stable operation of the power system, realize the status maintenance, reduce the maintenance cost and power outage time, and improve the management level.

3) Unique structure, easy installation and use.

The monitor adopts a completely closed design, unique and beautiful appearance, and the sensor, power supply, data output circuit and monitoring display are installed in the same housing, which directly displays the volume ratio value of water content (some models of transmitters). It is waterproof, anti-dust, anti-explosion, anti-strong electromagnetic interference, easy to install and use, and can be used in high-frequency electric field environment and outdoor environment.

Technical parameter

Pressure range: 0.000MPa ~ 1.000 Mpa, pressure accuracy: resolution: 0.001Mpa, better than 1 level; Dew point measurement: -80℃ ~ 20℃, measurement accuracy: ±1℃; Resolution: 0.1 Alarm threshold: 0.52MPa or custom, alarm release: 0.53MPa or custom, lock threshold: 0.50MPa or custom.

EN

EN

上一条:

上一条:

沪公网安备31011802003762

沪公网安备31011802003762