专注于SF6气体检测的专业化

Difference between pressure gauge and density relay

pressure gauge (English name :pressure gauge) refers to the elastic element as a sensitive element, measuring and indicating higher than the environmental pressure of the instrument, the application is very common, it is almost all industrial processes and scientific research fields. It can be seen everywhere in the fields of heat pipe network, oil and gas transmission, water supply and gas supply system, vehicle maintenance factory and so on. Pressure gauge is an instrument that is used to measure greater than atmospheric pressure based on atmospheric pressure. Pressure gauge is a common measuring instrument, can intuitively show the pressure changes in each process, insight into the formation of conditions in the product or medium process, monitor the safety trend in the production and operation process, and through the automatic chain or sensing device, build a rapid and reliable safety guarantee, to prevent accidents, protect personal and property safety has played an important role. It is called the "eyes" of security.

Pressure gauge is a monitoring function, that is, the detection of system pressure, density relay is on the one hand is to monitor the change of system density, can be set with alarm contact and locking contact, on the other hand is to control and protect the role. That's the difference between the two.

SF6 gas density table: In a closed container, the SF6 gas pressure at a certain temperature can represent the density of SF6 gas. It is customary to take the SF6 gas pressure at 20℃ as the standard value. In the field verification, under different ambient temperatures, the measured pressure value should be converted to its corresponding pressure value at 20℃ to judge the performance of SF6 density relay. Density relays play a controlling and protective role in monitoring electrical equipment. Generally, the domestic installation density meter monitors the open circuit or GIS leakage, and some pressure and gas density relays are combined to detect the leakage of equipment.

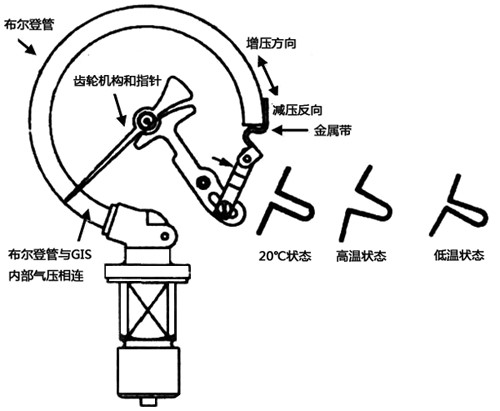

SF6 density detection is the use of Bourdon tube pressure measurement, Bourdon spring or Bourdon tube is a hollow coil spring, gas from the inlet into the Bourdon spring, forcing the spring to extend, drive the pendulum rod to move left, push the gear rod counterclockwise rotation, the needle deflecting clockwise, indicating the pressure reading. If the pressure rises, the Bourdon spring extends further so that the needle continues to deflector clockwise. If the pressure is reduced, the Bourdon spring contracts, moving the pendulum bar to the right, rotating the gear bar clockwise and deflecting the pointer counterclockwise.

In the absence of leakage in equipment filled with SF6 gas, a change in temperature will cause a change in pressure. If the ambient temperature decreases, the pressure will decrease; conversely, if the ambient temperature increases, the pressure will increase. In the absence of temperature compensation, if the equipment leaks air, but the ambient temperature is high, the meter still indicates the specified pressure, if the equipment does not leak air, but the ambient temperature is low, the meter will indicate lower than the specified pressure. In this way, it is not possible to correctly determine whether the equipment is leaking. In order to detect whether the equipment is leaking, it is necessary to use compensation devices to eliminate the influence of temperature changes on the pressure indication.

SF6 gas density relay structure principle and use precautions, combined with examples and national standards in-depth analysis of SF6 electrical equipment using SF6 gas density relay and SF6 gas density meter instead of ordinary pressure gauge reasons.

Density refers to the mass per unit volume of a given substance under a given condition. The SF6 gas in SF6 appliances is sealed in a stationary container. At the rated pressure of 20 ° C, it has a certain density value, and within the range of allowable conditions for the operation of the appliance, although the pressure of SF6 gas changes with the change of temperature, the density value of SF6 gas is always unchanged. Because the insulation and arc extinguishing performance of SF6 circuit breakers depends largely on the purity and density of SF6 gas, it is particularly important to detect the purity of SF6 gas and monitor the density. In order to achieve the purpose of frequently monitoring its density, as mentioned above, the national standard clearly stipulates that the SF6 circuit breaker should be equipped with a density relay or gas density meter. The SF6 gas density meter plays a monitoring role, and the gas density relay plays a control and protection role.

The symbol for density is ρ and the unit symbol is kg/m3 or g/L. According to the definition of density, the indication value of the SF6 gas density table should be a unit of density. However, at present, the indicator value of the density table produced and used at home and abroad is the unit of pressure MPa. From the data collected by the existing means of inquiry, there is no unified technical standard for the density table in the country, and there is no technical standard for the density table abroad.

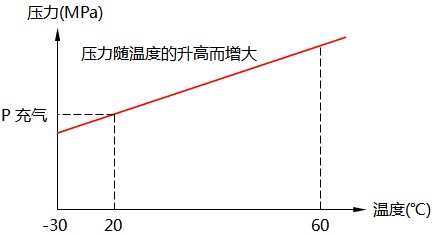

According to the ideal gas equation of state pv=nRT, it can be seen that the pressure p is a linear relationship of temperature. As shown in the figure below, when the gas temperature in the sulfur hexafluoride equipment changes, the value of the pressure gauge changes with the change, and it is not ready to show the state of the equipment. Structure principle of sulfur hexafluoride gas density relay

Structure principle of sulfur hexafluoride gas density relay

Sulfur hexafluoride gas density relay (table) is a sulfur hexafluoride circuit breaker and sulfur hexafluoride electrical combination (Table).GISAn indispensable and important annex. Its basic function is to monitor the sealing status of SF6 appliances in operation and whether there is gas leakage. As shown in the figure below, the structure of the compensation chip type sulfur hexafluoride density relay

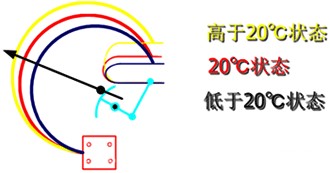

SF6 gas density relay (table) is mainly composed of spring metal curved tube, gear mechanism and needle, double metal belt and other parts, in fact, on the basis of the spring tube type pressure gauge structure principle, install a double metal belt in accordance with the change of ambient temperature and expansion as a temperature compensation device. The increment of the spring tube and the double metal strip that expand and expand with the change of temperature is equal and reversed, so that the density (pressure) reading does not change with the change of the ambient temperature. Sulfur hexafluoride density relay structure Temperature compensation principle SF6 gas density relay is actually a pressure relay with temperature compensation, and its density value is expressed by the corresponding pressure value of 20℃. When the temperature changes, the elastic Bourdon tube and metal band change at the same time, so that the pointer displays unchanged. In the case of constant volume, any pressure change due to temperature change alone can be compensated by the corresponding change of Bourdon tube and metal sheet at the same time, so as not to cause the deflection of the pointer and ensure the correctness of the pressure indication value. As shown in the following picture.

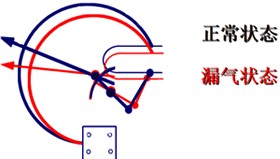

The response of the pressure element to any pressure change that is not caused by a temperature change is translated into the gas density relay pointer action and reflected on the dial, and the pressure value beyond the minimum or maximum pressure allowed by the system can be monitored. Air leakage as shown below.

The requirements of the new 18 anti-measures of the State Grid on the structure of sulfur hexafluoride density relay: The density relay should be installed in the same operating ambient temperature position as the monitored gas chamber. Explanation: If the operating environment temperature is different, the compensation temperature of Bourdon tube and metal strip is inconsistent, resulting in inaccurate values. General requirements for sulfur hexafluoride electrical appliances According to DL/T728-2013 "Gas insulated metal enclosed Switchgear ordering Technical Guidelines" and the former Ministry of Energy issued "High voltage circuit breaker operating Regulations" and other standards, the general requirements for sulfur hexafluoride electrical appliances (for convenience, the sulfur hexafluoride electrical appliances described in this article basically refer to SF6 circuit breakers and GIS) are: 1, monitoring the change of SF6 gas pressure, should be set up density relay or gas density meter. 2. The density monitoring device can be a density meter or a density relay. When a density relay is selected, a gas density meter should also be installed. 3. Check and record the pressure and temperature of SF6 gas regularly every day. According to Weavers' statistics on nearly five hundred SF6 density tables in a power supply bureau, this is the case for imported Swiss ABB tables, German WIKA, CBS, Xi 'an Huawei, Shanghai Keli and other origin instruments. The spring-tube pressure gauge has a pressure drop alarm caused by air leakage and an electrical contact that is blocked to form the SF6 gas density relay. Density relays are used for monitoring with gas density gauges and for alarm and latching elements. From the existing experience and theoretical analysis, the SF6 gas density relay with this structure is adopted on the basis of the following: 1. Although the pure pressure-temperature curve of SF6 gas (that is, the three-phase physical diagram of SF6 gas, liquid and solid) is more complex, the relationship between the pressure of SF6 gas and the change of absolute temperature is still linear within a certain temperature range. Therefore, each equipment manufacturer adopts the actual use of SF6 gas pressure-temperature curve, that is, the pressure of SF6 gas changes with the change of temperature, and there is a 10%-15% error allowed by the standard, but in a fixed and unchanged container, as long as there is no leakage phenomenon, the density value of SF6 gas is always unchanged. The density value of SF6 gas is proportional to the function of the pressure value. Therefore, it is theoretically feasible to monitor whether the equipment leaks gas with the pressure value. 2, the spring tube pressure gauge has the characteristics of simple structure, mature manufacturing process and technical standards, accurate measurement, low cost, etc., suitable for large-scale manufacturing and use. When the circuit breaker is filled with sulfur hexafluoride gas, generally 24 hours later, the internal temperature of SF6 circuit breaker rises to reach a balance with the external ambient temperature, regardless of whether the SF6 gas is affected by the ambient temperature, its pressure increases or decreases, due to the temperature compensation effect of the double-layer metal strip. The needle of the gas density meter should always point to the actual density (pressure) value of SF6 gas at 20 ° C. When the SF6 device reduces the mass of SF6 gas and the pressure due to gas leakage or test taking, the pointer moves in the direction of the decrease of the density (or pressure) indicator value, the result is that the density (or pressure) value indicated by the pointer becomes smaller.

EN

EN

上一条:

上一条:

沪公网安备31011802003762

沪公网安备31011802003762