专注于SF6气体检测的专业化

What are the precautions for SF6 density relay inspection?

The SF6 gas density relay, like other manometers, will have a certain drift in its alarm and latching values after a period of use; In addition, because the contact action of the density relay is not frequent, the contact action may be insensitive or ineffective. If not inspected, there is a security risk.

Check the density relay using the SF6 device charging process:

(1) Temperature has a large impact, and it is difficult to ensure accuracy.

(2) Using the meter reading on the SF6 gas cylinder, the accuracy is very poor, and the accuracy cannot be guaranteed.

(3)SF6 density relays are actually used in the step-down process, and using the inflation process to test is inconsistent with the actual application, and also affects the accuracy of the test.

2. The use of SF6 equipment gas recovery process to test the density relay with this method has the same problem as in 1 (1), (2), and when deflating to recover SF6 gas, need to use a special SF6 gas recovery device, very inconvenient. There are also precision issues.

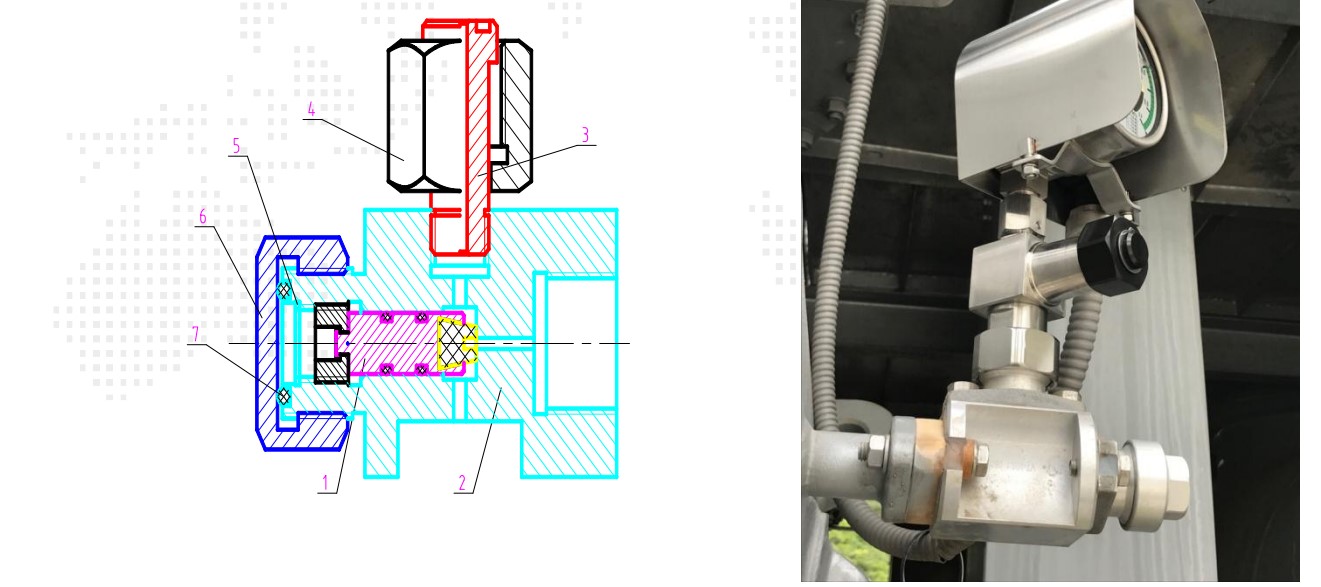

In order to ensure the safety of the calibration work, the following matters should be paid attention to during the on-site calibration of SF6 density relay: 1) On-site check the SF6 density relay gas path structure and find out how to cut off the gas path.

2) A work ticket should be issued.

3) For SF6 density relays with isolating valves on the gas path, close the isolating valves.

4) For SF6 density relays with check valves, disengage.

5) In the SF6 density relay calibration work should be carried out alarm, lock circuit action inspection test.

6) After the verification work, the staff must use the leak detector to detect the leak and ensure the tightness.

7) The SF6 density relay calibration device should be dedicated and cannot be used for the verification of other pressure working instruments, especially oil pressure gauges.

8) The temperature should be balanced by the appropriate time.

9) Must be carried out in accordance with the verification process, the principle is: first break the density relay and switch gas path, and then connect the relay with the test instrument to ensure that the whole process is sealed and safe.

10) For the valve type switch, after the check is finished, the principle is: first close the valve or plug of the check port, and then open the valve connected with the relay to ensure that the whole process is sealed and safe, and ensure that the valve is open when running.

11) Check the wiring number of the alarm or lock contact at the scene.

12) Pay attention to the working position when connecting. (As with microwater, standing...)

13) Timely record the electrical wiring, gas path direction, transition joint number, sealing ring (can be replaced at any time) of density relays of different models and manufacturers to establish a database.

14) For the pointer density relay, the rating value and the contact action value can be checked. (For a density relay, it is also necessary to check the starting point, especially in cold areas).

15) To understand the types of density relays, especially in some areas.

16) For the verification of SF6 pressure gauge, the actual pressure should be compared.

EN

EN

上一条:

上一条:

沪公网安备31011802003762

沪公网安备31011802003762