专注于SF6气体检测的专业化

Causes of partial discharge of GIS

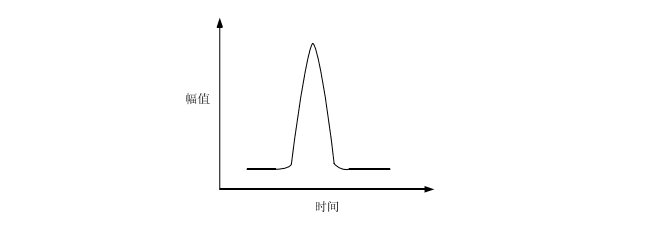

Partial discharge is generally caused by the insulation defects or weaknesses in the electrical equipment, which refers to the discharge between the electrodes and does not form through the channel, and under the action of a strong electric field, there will be repeated breakdown and extinction. Partial discharge is caused by the breakdown of a small range of solid or liquid media, the breakdown of the bubble inside the insulation and the concentration of the surface electric field at the metal edge. The range of partial discharge is very small, the energy generated when the discharge occurs is very little, and the insulation will not be broken down in the short term. However, with the passage of time, the cumulative effect will lead to the amplification of insulation defects, resulting in insulation breakdown. Among them, surface partial discharge refers to the partial discharge that occurs on the surface of the insulator. Internal partial discharge refers to the partial discharge that occurs inside the insulator. Corona discharge occurs near a conductor surrounded by gas, and the strength of the electric field exceeds the ionization strength of the surrounding gas. As shown in the figure, the duration of partial discharge is short, less than 1s, and appears as a pulse.

In summary, partial discharge has the following characteristics:

(1) The energy generated by partial discharge is very small, and the development time from partial discharge to insulation breakdown needs to be longer, which will not cause harm to the insulation strength of electrical equipment in the short term;

(2) The insulation damage to electrical equipment has a cumulative effect, and the development process is: cumulative effect - insulation expansion - insulation breakdown.

Partial discharge refers to the phenomenon of local discharge or breakdown in the insulating medium due to uneven electric field distribution and high local electric field in the insulation structure.

It may be produced in solid insulating pores, liquid insulating bubbles, or between insulating layers with different dielectric characteristics. It can also occur in liquid or solid insulation if the electric field strength is higher than a specific value that the medium has.

Partial discharge gradually develops, through the continuous erosion of the insulating medium around it, eventually leading to the failure of the entire insulation system, so partial discharge is the main cause of insulation deterioration, and it is also an important sign and manifestation of insulation deterioration, closely related to the deterioration and breakdown process of insulation materials, and can effectively reflect the internal insulation failure of power equipment. In particular, the early detection of sudden faults is much more effective than the measurement of dielectric loss and the analysis of gas content in oil.

Main causes:

l fixed particle on the wire;

A fixed particle on the shell;

l Floater (bad galvanic contact);

l The free part on the insulator;

l Holes between the screen and the insulator (separation of layers);

l Holes and irregular metal deposits in insulators.

EN

EN

上一条:

上一条:

沪公网安备31011802003762

沪公网安备31011802003762