专注于SF6气体检测的专业化

Wevers-china Huadian [Xixihe Lianbu Power Station]

one Project overview

Xixi River is a tributary of the lower left bank of the Jinsha River, flowing through Yuexi, Zhaojue, Butuo and Jinyang counties in Liangshan Prefecture. The Xixi River Basin plans to develop two five-level cascade hydropower stations, from top to bottom: Kuyi Reservoir power station, Luogu Reservoir Power station, Lianlian water supply power station, Deluo Hydropower station and Qingsong Hydropower station, with a total installed capacity of 473,000 kW, which will be integrated into the Sichuan main network. The cascade power stations have been built for Luogu, Lianbu, Diluo three hydropower stations, with a total installed capacity of 340,000 kW, distributed in Zhaojou County, Butuo County, Jinyang County, Liangshan Prefecture, Sichuan Province.

Project 1: Transformation and calibration of SF6 density relay in Diluo, Lianbu and Luogu power stations

According to Article 13.1.6 of the "25 Key Requirements of the National Energy Administration on Preventing power Production Accidents" (National Energy Safety (2014) No. 161), the connection between the sulfur hexafluoride density relay and the switchgear body should meet the requirements of not disassembling the check density relay. At present, the SF6 circuit breaker density relay of the basin power station does not meet the connection mode and inspection conditions required by the reverse method. It is necessary to improve the online monitoring system of SF6 density relays of the three hydropower stations of the basin power station, Diluo, Lianbu and Luogu, so as to realize the requirement of online detection and verification without disassembly of the density relays.

Project 2: Renovation of SF6 leakage monitoring and alarm system of Lianbu power Station

The SF6 gas leak detection monitoring and alarm system of the generator outlet circuit breaker room of Lianbu Power Station adopts the PBS-G-02 device produced by Sichuan Feibosi Technology Co., LTD. It is composed of one alarm system host and four oxygen and SF6 gas content detection sensors (electronic type). It was officially put into operation in July 2011 and has been in operation for 5 years. SF6 gas leakage alarm system often has problems such as black screen, difficult to enter the system after returning, unable to restore the setting after entering the system, false alarm and crash. After many times with the manufacturer of Sichuan Feibosi Technology Co., Ltd. technical personnel to confirm that the product has failed, the equipment has not been produced, can not be repaired, there are serious security risks. Need to be replaced.

Weavers Detection adopts SF6 leak monitoring and alarm system produced by Shanghai Zhongyo Intelligent Technology Co., LTD. The successful installation of the system effectively guarantees the safety of the environmental personnel and equipment in the substation, and raises the whole substation environment and indoor operation to a new level.

Renovation period requirement

1. After the equipment contract is signed, the manufacturer personnel will check the technical data of the equipment on site within 7 days;

2, the production cycle of the equipment is 30 days (working days), should be shipped to the power station site 3 days before the expected installation and commissioning time.

3. The on-site installation and commissioning will be carried out during the shutdown of the switching stations of Luogu Power Station, Lianbu Power Station and Deluo Power Station, which is expected to take 12 days.

2. Engineering work content

2.1SF6 density relay modification

2.1.1 Scope and quantity of transformation

Station name | Serial number | Device name | Equipment type | Density relay type | quantity |

Logu power station | 1 | 220kV Jiupu line 251DL | LTB72.5-245E1(Single-phase operating mechanism BLK222) | LANSO DM 100P | 3 |

2 | 220kV connection line 252DL | LTB72.5-245E1(Single-phase operating mechanism BLK222) | LANSO DM 100P | 3 | |

3 | 1 main transformer 1B high pressure test 201DL | LTB72.5-245E1(Three-phase Linkage BLG1002A) | LANSO DM 100P | 3 | |

4 | The second main transformer 2B high voltage measurement 202DL | LTB72.5-245E1(Three-phase Linkage BLG1002A) | LANSO DM 100P | 3 | |

The connecting power station | 1 | 220kV connection line 251DL (Phase 1) | LTB72.5-245E1(Single-phase operating mechanism BLK222) | LANSO DM 100P | 3 |

2 | 220kV cable 252DL (Phase II) | LTB72.5-245E1(Single-phase operating mechanism BLK222) | LANSO DM 100P | 3 | |

3 | 220kV ground line 254DL (Phase II) | LTB72.5-245E1(Single-phase operating mechanism BLK222) | LANSO DM 100P | 3 | |

4 | No. 1 Main Transformer 1B High Pressure measurement 201DL (Phase I) | LTB72.5-245E1(Three-phase Linkage BLG1002A) | LANSO DM 100P | 3 | |

5 | No. 2 Main Transformer 2B High voltage measurement 202DL (Phase I) | LTB72.5-245E1(Three-phase Linkage BLG1002A) | LANSO DM 100P | 3 | |

6 | 220kV busbar switch 212DL (Phase II) | LTB72.5-245E1(Three-phase Linkage BLG1002A) | LANSO DM 100P | 3 | |

Dilo power station

Dilo power station | 1 | The high pressure side of main transformer 1B is connected to air chamber G52 | Shanghai Xi 'an High Voltage Electric Appliance Research Institute Co., LTD ZF1-252 220kV GIS | Shanghai Xinyuan instrument factory MTK-01 30W 50VA | 1 |

2 | No. 1 main transformer 1B high voltage circuit breaker 201DL air chamber GB5 | Shanghai Xi 'an High Voltage Electric Appliance Research Institute Co., LTD ZF1-252 220kV GIS | Shanghai Xinyuan instrument factory MTK-01 30W 50VA | 1 | |

3 | No. 1 Main Transformer 1B high pressure side isolation cutter brake 2011G air chamber G51 | Shanghai Xi 'an High Voltage Electric Appliance Research Institute Co., LTD ZF1-252 220kV GIS | Shanghai Xinyuan instrument factory MTK-01 30W 50VA | 1 | |

4 | Bus air chamber GM1 | Shanghai Xi 'an High Voltage Electric Appliance Research Institute Co., LTD ZF1-252 220kV GIS | Shanghai Xinyuan instrument factory MTK-01 30W 50VA | 1 | |

5 | 220kV ground line side isolation cutter gate 2516G air chamber G42 | Shanghai Xi 'an High Voltage Electric Appliance Research Institute Co., LTD ZF1-252 220kV GIS | Shanghai Xinyuan instrument factory MTK-01 30W 50VA | 1 | |

6 | 220kV ground line circuit breaker 251DL air chamber GB4 | Shanghai Xi 'an High Voltage Electric Appliance Research Institute Co., LTD ZF1-252 220kV GIS | Shanghai Xinyuan instrument factory MTK-01 30W 50VA | 1 | |

7 | 220kV ground line bus side isolation tool brake 2511G air chamber G41 | Shanghai Xi 'an High Voltage Electric Appliance Research Institute Co., LTD ZF1-252 220kV GIS | Shanghai Xinyuan instrument factory MTK-01 30W 50VA | 1 | |

8 | 220kV bus isolating tool brake 218G air chamber G31 | Shanghai Xi 'an High Voltage Electric Appliance Research Institute Co., LTD ZF1-252 220kV GIS | Shanghai Xinyuan instrument factory MTK-01 30W 50VA | 1 | |

9 | 220kV bus PT218 gas chamber G32 | Shanghai Xi 'an High Voltage Electric Appliance Research Institute Co., LTD ZF1-252 220kV GIS | Shanghai Xinyuan instrument factory MTK-01 30W 50VA | 1 | |

10 | 220kV bus arrester gas chamber G33 | Shanghai Xi 'an High Voltage Electric Appliance Research Institute Co., LTD ZF1-252 220kV GIS | Shanghai Xinyuan instrument factory MTK-01 30W 50VA | 1 | |

11 | No. 2 main transformer 2B high pressure side is connected to gas chamber G22 | Shanghai Xi 'an High Voltage Electric Appliance Research Institute Co., LTD ZF1-252 220kV GIS | Shanghai Xinyuan instrument factory MTK-01 30W 50VA | 1 | |

12 | No. 2 main transformer 2B high voltage side circuit breaker 202DL air chamber GB2 | Shanghai Xi 'an High Voltage Electric Appliance Research Institute Co., LTD ZF1-252 220kV GIS | Shanghai Xinyuan instrument factory MTK-01 30W 50VA | 1 | |

13 | No. 2 main transformer high pressure side isolation cutter brake 2021G air chamber G21 | Shanghai Xi 'an High Voltage Electric Appliance Research Institute Co., LTD ZF1-252 220kV GIS | Shanghai Xinyuan instrument factory MTK-01 30W 50VA | 1 | |

14 | 220kV green ground line side isolation knife 2526G gate air chamber G12 | Shanghai Xi 'an High Voltage Electric Appliance Research Institute Co., LTD ZF1-252 220kV GIS | Shanghai Xinyuan instrument factory MTK-01 30W 50VA | 1 | |

15 | 220kV blue ground circuit breaker 252DL air chamber GB1 | Shanghai Xi 'an High Voltage Electric Appliance Research Institute Co., LTD ZF1-252 220kV GIS | Shanghai Xinyuan instrument factory MTK-01 30W 50VA | 1 | |

16 | 220kV green ground bus side isolation tool brake 2521G air chamber G11 | Shanghai Xi 'an High Voltage Electric Appliance Research Institute Co., LTD ZF1-252 220kV GIS | Shanghai Xinyuan instrument factory MTK-01 30W 50VA | 1 | |

Total (only) | 46 | ||||

2.1.2SF6 density relay transformation implementation plan

1) Introduction of SF6 density relay online calibration system

SF6 density relay online calibration system is not changing any of the original structure of the switch, through the switch SF6 density relay interface, add a combination valve with a breaking device, The valve is provided with a connector for the original SF6 density relay interface, a SF6 density relay connector, a breaking device and a connector for a special SF6 density relay calibrator. After the connection is made according to the design requirements, the gas path of SF6 density relay and the gas path of switch body can be realized by rotating the breaking device. When it is necessary to verify the SF6 density relay, it is necessary to rotate the breaking device on the valve body to the closed state, and then complete the connection between the calibrator interface and the calibration interface reserved on the valve body, so as to realize the calibration of SF6 density relay, which can greatly save the precious time of maintenance personnel. It can also greatly reduce the risk of SF6 gas leakage due to regular verification disassembly.

2) Main technical indicators of SF6 density relay online calibration system

● Pressure rating: PN64

● Valve material: Aluminum alloy, stainless steel

● Ambient temperature: -40℃ ~ +60℃

● Sealing performance: absolute leakage rate ≤ 1× 10-9Pa? m3/s

● Life span: 800 times

● Sealing form: metal seal, O-ring seal

● Installation interface: customized according to user requirements

● Product shape: customized according to user requirements

3) Transformation plan and process

1. Formulation of transformation plan

(1) Before formulating the scheme, it is necessary to conduct on-site surveying and mapping, mainly collecting information such as the detailed dimensions of the installation interface and the layout of other surrounding components. After the contract is signed, our company will send relevant technical personnel to the scene, and we need your relevant personnel to fully cooperate and do the necessary protection and safety training.

(2) After the plan is completed, our company will communicate with you in the form of plane plan and 3D model screenshot, until it meets your review and approval, and sign for confirmation.

2. General introduction of the transformation plan

According to the relevant information of your Luogu and connected power substation, the switch model used for 220kV is produced by ABB company. Below, our company will introduce the scheme made for Changchun Power Supply Bureau in the previous period (ABB switch) :

The structure diagram of SF6 density relay online calibration system is reformed

Three-dimensional model diagram

Illustration: Connector 1 is reserved port, connected with the original SF6 density relay; Connector 2 is connected to the self-sealing valve at the original SF6 density relay interface; Connector 3 is a reserved port, which is connected to the SF6 density relay calibrator; The operation handle is used to control the on-off between the body gas path and the SF6 density relay gas path and the gas path of the calibrator. This function is realized by rotating, and there is an obvious mark on the valve body; As requested by you, in order to prevent misoperation, we will add this function in this scheme by adding a special mechanism on the operating handle. If the operation of rotating the handle is to be performed, the mechanism must be unlocked.

3, anti-error lock structure design

3. Reform implementation plan

(Xixi River Basin Diluo Station SF6 anti-false lock valve control tee joint design schematic)

The scheme of Luogu and connected substations is roughly the same as the scheme shown above. We will optimize the scheme according to the relevant data after surveying and mapping. The scheme of Deluo Power station needs to be designed after surveying and mapping. We will give priority to selecting the combined valve that can meet the switch from the pre-reformed scheme, which can greatly shorten the design and processing cycle. After the product is completed, we will send a project specialist specializing in the renovation project to the substation for construction. The implementation steps are roughly as follows:

1. Replace the switch when the switch is not charged. Remove the SF6 density relay from the interface of the original SF6 density relay. The lower interface is a valve with self-sealing structure. In order to prevent SF6 gas leakage caused by the failure of the self-sealing valve, take certain protection when removing the switch.

2. Connect the SF6 density relay to the combined valve interface 1. Before connecting, clean all O-rings, apply appropriate amount of vacuum silicone grease, adjust the direction, and tighten the nut.

3. Unlock the anti-error mechanism on the handle, rotate the handle, and the arrow on the handle points “ OFF” .

4. Hold the connector firmly, insert connector 2 into the self-sealing valve at the original SF6 density relay interface of the switch, adjust the direction, and tighten the nut.

5. Turn the handle to “ ON” At this time, the gas circuit of connector 1, connector 2 and connector 3 is connected, and the SF6 density relay normally displays the density value of SF6 gas in the switch.

6. Use SF6 qualitative leak detector to detect the connection position and all leakage points.

7. Install the rain cover according to the design scheme after the leak detection is qualified.

8. Turn the handle to “ OFF” At this time, the gas path of connector 2 and 3 is disconnected from connector 1, and the gas path of connector 2 and connector 3 is normal. Connect the SF6 density relay calibrator interface with connector 3, and verify the SF6 density relay through the internal air source of the calibrator. After the docking is completed, operate in strict accordance with the instructions of the calibrator, and verify the SF6 density relay. Remove the calibrator after passing the check, turn the handle to “ ON” Position, use the tool to tighten the anti-error mechanism on the operating handle.

9. Certain spare parts should be prepared in advance, and the unqualified SF6 density relay should be replaced in time.

2.1.5 Compliant Technical Standards

The inspection equipment, inspection interface and field installation test of SF6 density relay provided by the supplier must comply with the latest version of the following standards:

Serial number | Standard code | Standard name |

1 | DL/T 1366 | Sulfur hexafluoride gas for electric power equipment |

2 | DL/T 259 | Calibration procedure for sulfur hexafluoride gas density relays |

3 | DL/T 639 | Sulfur hexafluoride electrical equipment operation, test and maintenance personnel safety protection rules |

4 | GB 11023 | Test method for sulfur hexafluoride gas seals for high voltage switchgear |

5 | JB/T 7052 | Rubber seals for high voltage electrical equipment sulfur hexafluoride rubber seals for electrical equipment Technical conditions |

6 | DB41/T1041 | Pressure type sulfur hexafluoride gas density controller calibrator |

2.1.6 Device Requirements

1) The special combined valve-controlled tee interface equipment should work reliably and meet the mechanical strength requirements required for non-disassembly inspection.

2) When the special combined valve-controlled tee joint leaves the factory, the inside should be treated with water removal and dust removal, and the outside should be packaged with a self-sealing bag and add a desiccant.

3) The special combined valve-controlled tee is filled with high purity SF6 gas inside the factory, and the pressure is > 0.4MPa.

4) The special combined valve control three-way joint manual valve should have the function of preventing misoperation.

The provided SF6 density relay inspection equipment has been inspected by a third-party inspection unit and submitted an inspection report to ensure that the SF6 density relay inspection meets the requirements.

3.3 The list of tools involved in engineering renovation is as follows:

Serial number | Device name | Specification and model | quantity | unit | remark |

1 | SF6 quantitative leak detector | 1 | Set of | Provided by Huadian | |

2 | multimeter | UT9201 | 1 | Taiwan | Provided by Weavers |

3 | 50mm adjustable wrench | 1 | Taiwan | Provided by Huadian | |

4 | Electrician's routine kit | - | 1 | Set of | Provided by Weavers |

5 | Insulated ladder | 1 | a | Provided by Huadian |

4. Construction period and personnel division

According to the contract requirements, all the materials required in this project have arrived at the construction site on March 17, 2016. Wevers Testing Technology (Shanghai) Co., Ltd. appointed two project managers and one installation service personnel to arrive at the construction site on March 17 with special tools.

According to the power outage plan of Huadian Company, from March 18 to March 19, a total of 16 sets of combined valved-controlled tee joints were installed in the Diluo Water Power Station in Xixi River Basin. Strict gas tightness test was carried out after the installation, and no SF6 gas leakage was found at all installation points. And by the responsible Jiang Gong, Wei Gong for inspection and acceptance.

According to Huadian Company's power outage plan, from March 20 to March 23, the technical transformation of the Xixi River basin Diluo water power station was carried out. A total of 18 sets of combined valv-controlled tee joints were installed. Strict gas tightness test was carried out after installation, and no SF6 gas leakage was found at all installation points. Then the lines and other parts were restored according to the requirements of the equipment drawings, and Yang Gong (Yang Yang) was the person in charge. 2 A total of 4 SF6 monitors and 1 temperature and humidity monitor are installed in the 1# switch room and 2# switch room of the generator, and 1 control host is installed outdoors. After installation, the equipment is debugged and functional test is carried out. All indicators are running normally, and Fan Gong (Fan Long) and Li Gong (Li Yong) in charge of the inspection and acceptance are carried out.

According to the power outage plan of Huadian Company, from March 23 to March 25, a total of 16 sets of combined valv-controlled tee joints were installed in the Diluo Water Power Station in Xixi River Basin. Strict gas tightness test was carried out after the installation, and no SF6 gas leakage was found at all installation points. And by the responsible Jiang Gong (Jiang Xu), Wei Gong (Wei Xiangyi) for inspection and acceptance.

5. Acceptance contents and standards

5.1 Diluo Power Station SF6 density relay renovation project

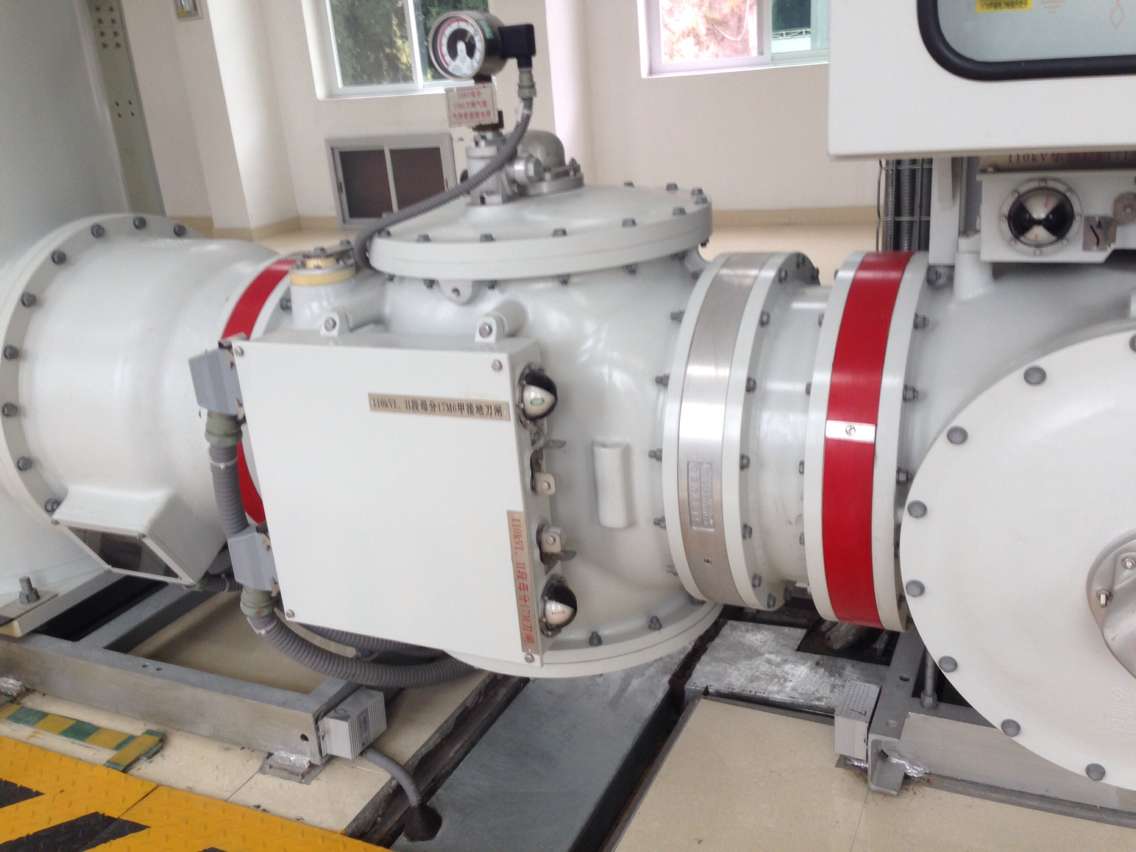

5.1.1 A total of 16 sets of combined valve control tee joints were installed in GIS switch room of Deluo Power Station. Strict gas tightness test was carried out after installation, and no SF6 gas leakage was found at all installation points. Then lines and other parts were restored according to the requirements of equipment drawings, as shown in FIG.1 and 2.

Figure 1 Busbar gas chamber GM1 equipped with combined valve-controlled tee Figure 2 The leakage position of SF6 is detected

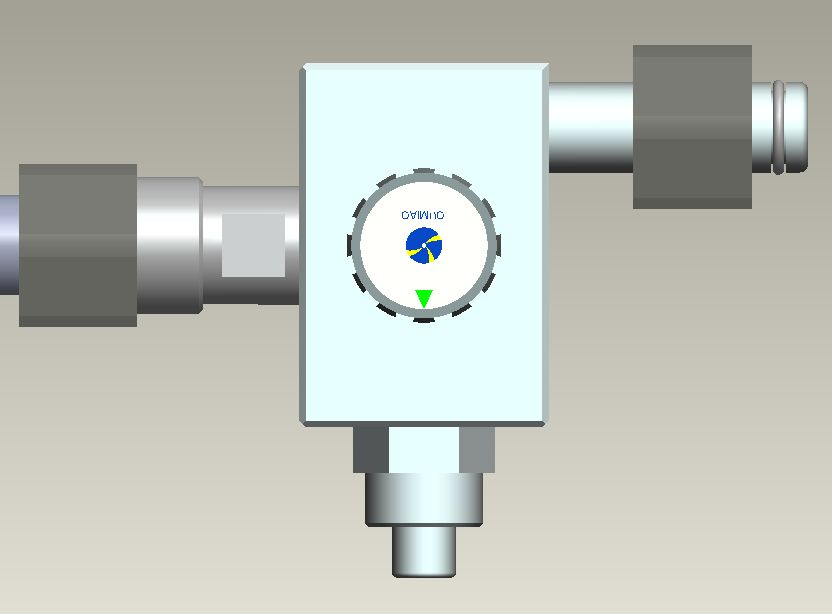

5.1.2 The SF6 density relay calibrator, model JOY-A22, produced by Shanghai Zhongyue Intelligent Technology Co., LTD., a subordinate service company of Wevers, was used to verify 16 density relays in Diluoshui Power Station, as shown in Figure 3 below. The test results were all qualified.

Figure 3 Verifies the SF6 density relay

5.2 Transformation project of SF6 density relay and SF6 leakage alarm system of Xixi River Basin combined water supply Power Station

5.2.1 A total of 18 sets of combined valv-controlled tees were installed in Lianlian water supply power station. Strict gas tightness test was carried out after the installation, and no SF6 gas leakage was found at all installation points. Then the lines and other parts were restored according to the requirements of the equipment drawings, as shown in Figure 4:

Figure 4 Add a combined valve-controlled tee

5.2.2 The SF6 density relay calibrator of model JOY-A22 produced by Shanghai Zhongyo Intelligent Technology Co., LTD., a service company affiliated to Wevers Company, was used to verify 18 density relays in the United water supply station. The specific data of the inspection results are shown in Annex 1.

5.3 Transformation project of SF6 density relay in Luogu Power Station

5.2.1 A total of 12 sets of combined valve-controlled tee joints were installed in Luogu Hydropower Station. Strict gas tightness test was carried out after the installation, and no SF6 gas leakage was found at all installation points. Then the lines and other parts were restored according to the requirements of the equipment drawings, as shown in Figure 6:

Figure 6 Add a combined valve-controlled tee

5.2.2 The SF6 density relay calibrator, model JOY-A22, produced by Shanghai Zhongyo Intelligent Technology Co., LTD., a service company affiliated to Wevers Company, was used to verify 16 density relays in Lugu Power Station. The specific data of the inspection results are shown in Annex 1.

6. Project completion acceptance opinions

Project name | Renovation of 220kV, 10kV SF6 circuit breaker density relay online monitoring system for watershed power station | |||

Contract date | February 5, 2016 | Planned date | From March 18 to March 28, 2016 | |

Owner's unit | Sichuan Huadian Xixi river electric development company | Construction unit | Weavers Testing Technology (Shanghai) Co., LTD | |

Commencement date | March 18, 2016 | Date of completion | ||

Brief content of project: 1, Diluo water power Station SF6 density relay renovation project 2. SF6 density relay renovation project of Lianhe Water supply power Station 3. SF6 leakage alarm system renovation project of Lianhe Water replenishment power Station 4, Luogu hydropower Station SF6 density relay renovation project | ||||

Project completion status: The above project has been completed by the project manager and engineering personnel of Wevers Testing Technology (Shanghai) Co., Ltd. according to the contract requirements, there is no violation of operation rules in the construction process, and the requirements of safety and technical measures are met. There is no delay in the project. After the joint on-site inspection by both parties, the site has passed the preliminary acceptance and qualified, all the relevant sites have been restored, all the remaining equipment and materials have been cleared, the relevant operation and maintenance personnel have been trained, the technical data involved in the project has been sorted out, and the handover work has been completed. Therefore, we hereby apply for the completion of the project. | ||||

There are no remaining problems, and corresponding solutions and plans:

| ||||

Opinions and signatures of the acceptor of Diluo Power Station:

Year month day | Opinions of Deluo Power Station and signature of the person in charge:

Year month day | |||

Comments and signature of the acceptor of the auxiliary power station:

Year month day | Comments and signature of the person in charge of the auxiliary power station:

Year month day | |||

Comments and signature of the acceptor of Luogu Power Station:

Year month day | Logu Power Station opinion and signature of the person in charge:

Year month day | |||

Opinions of the construction unit and signature of the person in charge:

Year month day | Owner's opinion and signature of person in charge:

Year month day | |||

Approval by competent authorities

Year month day | ||||

Seven. After-sales service clause

1. In order to implement “ Focus, depth, excellence ” According to the Quality Law of China, the Law on Protection of Consumer Rights and Interests and the relevant provisions of the Three Guarantees of China, the Terms of Service are formulated.

2.WINFOSS products during the warranty period, the user in compliance with the product use, maintenance requirements, due to product design, manufacturing, raw materials, processing assembly, commissioning and other quality problems, WINFOSS is responsible for return, replacement, repair (referred to as three guarantees). The general principle of three guarantees: quality problems within 7 days are guaranteed. Quality problem replacement within 30 days. If the quality problem can be repaired within 18 months, it should be repaired mainly, and the performance requirements of the factory should be reached after repair.

3. The detailed rules shall be implemented by WINFOSS Customer Service Center and supervised and managed by Quality Assurance Department.

4.WINFOSS products are delivered according to the provisions of China's national standards, and products with special requirements are produced according to the standard requirements of the supply technology agreement.

5. The product is issued a certificate of qualification, and the packaging meets the requirements and regulations of the industry standards (cross-border products meet the import and export requirements).

6. Within 7 days from the date of receipt of the product, the product under normal use conditions, functional failure, the user can choose to return, replace or repair with a valid invoice.

Seven. Free refund product service regulations are as follows:

① From the date of purchase, within 7 days of normal use of the product with performance failure;

② Products damaged by non-human factors without dismantling and maintenance;

③ The appearance is not bad, warranty stickers, body bar code and other intact products;

④ Product return service, machine accessories (packaging materials, wire, manual and other accessories) complete.

8. The following conditions will not be covered by the return service:

① No contract and invoice, no user information archive products;

② The contract and invoice do not conform to the product model, and the data have traces of alteration;

③ Damage caused by human factors, including products damaged by failure to operate and use according to the instructions;

④ Disassemble the machine for maintenance and modification, and repair the damaged products at non-WINFOSS guaranteed maintenance points;

⑤ For the performance of the appearance of damage stains, not to be returned;

⑥ Improper use of the environment or conditions, such as power supply, ambient temperature, humidity, etc., resulting in damage to the product;

⑦ Products damaged by unavoidable factors, such as fire, flood, lightning, traffic accidents, etc.;

⑧ Products sold for more than 7 days.

⑨WINFOSS indicates that the products do not provide after-sales service, only assist in maintenance, no return.

9. Products under normal use conditions, the implementation of “ Complete machine warranty for 18 months ” Policy Free warranty product service regulations are as follows:

① Products with performance failure within 18 months from the purchase of the product;

② Products damaged by non-human factors without dismantling and maintenance;

10. All products that need to be guaranteed, the user will express the equipment to WINFOSS company (online monitoring products can apply for WINFOSS service engineers on-site solution), meet the warranty conditions will not charge any maintenance fees.

11. WINFOSS is not liable for the following conditions “ Three guarantees ” Responsibility, will not be within the scope of free warranty service, if the need for maintenance will be reasonably charged the corresponding material costs and maintenance costs:

① No purchase and sales contracts and invoices, no user information archive products;

② Damage caused by human factors, including damaged products caused by failure to operate according to instructions under normal working environment;

③ Users privately disassemble the machine for maintenance, modification, non-WINFOSS service center repair caused by damaged products;

④ Improper use of the environment or conditions, such as power supply, ambient temperature, humidity, etc., resulting in damage to the product;

⑤ Products damaged by irresistible force due to unavoidable factors, such as fire, flood, lightning, traffic accidents, etc.;

12. Economic responsibility

①WINFOSS“ Three guarantees ” The economic loss of WINFOSS refers to the direct loss of damaged parts or complete machines caused by the quality problems of WinFOSS products;

② WINFOSS “ Three guarantees ” The product is given free repair or replacement of parts or whole parts, should be confirmed by the WINFOSS service center, belongs to the user's reasons to expand the quality of the accident can be charged according to the responsibility of the replacement parts of the cost of materials;

③ User put forward to WINFOSS “ Three guarantees ” When required, it should be serious and realistic, and the resulting economic losses should be borne by those who practice fraud.

13. “ Three guarantees ” Disputes shall first be settled by both parties through consultation, and where mediation is required, the principle of on-site and nearby settlement shall be adopted.

fourteen Deal with “ Three guarantees ” In the event that no final settlement can be reached through negotiation and the user holds different opinions on the division of responsibilities, the user may apply to the relevant competent authorities for appraisal and arbitration.

Fifteen. The above ordinances do not affect the statutory rights of users as consumers.

Attachment 3: Customer Training Record Number: WFS008

Training date | Training site | ||

Training mode | recorder | ||

attend personnel | |||

train content |

1, combined valve control tee joint principle and gas logic 2, SF6 density relay calibrator working principle 3. Operation and management of SF6 density relay calibrator 4, SF6 density relay calibrator repair and maintenance 5, SF6 density relay calibrator general fault diagnosis 6, SF6 leakage monitoring alarm system working principle 7. Operation and management of SF6 leak monitoring and alarm system 8. SF6 leak monitoring and alarm system repair and maintenance 9, SF6 leakage monitoring alarm system general fault diagnosis | ||

trainee sign | |||

remark (Non-participants) | |||

Annex 4: Handover list of engineering related technical data

Serial number | Technical information and/or item name | nature | Number of units/copies | receiver | remark |

1 | SF6 density relay calibrator | ___ | A set | ||

2 | SF6 density relay calibrator accessories | ___ | A set | ||

3 | SF6 density relay calibrator product specification | Paper/electronic version | part | ||

4 | SF6 density relay calibrator inspection report | Paper version | part | ||

5 | SF6 density relay calibrator type test report | Paper version | part | ||

6 | Factory inspection report of combined valve-controlled tee joint | Paper version | In two copies | ||

7 | Combined valve-controlled tee joint prevents false lock key | ___ | 12 | Dilol, Lianbu, Logu 4 each | |

8 | SF6 Leak monitoring alarm system product specification | Paper/electronic version | part | ||

9 | SF6 leak monitoring alarm system factory verification report | Paper version | part | ||

10 | SF6 leak monitoring alarm system host key | ___ | two | ||

11 | SF6 density relay calibrator calibration with SF6 gas | ___ | A bottle |

Note 1: Nature refers to the electronic version or paper version, such as paper version should indicate the original or copy.

Note 2: If there is an independent recipient, the independent recipient should sign in the Remarks column.

Recipient (signature) : Recipient (signature)

Handover Date:

EN

EN

上一条:

上一条:

沪公网安备31011802003762

沪公网安备31011802003762