专注于SF6气体检测的专业化

SF6 density relay retrofit without disassembly cal

Because the SF6 gas density relay's alarm and latching values will drift after being used for a certain period of time, and the temperature compensation material will be aging and deformed after being used for a certain period of time, the alarm and latching values will have a large error. In addition, because the density relay contact action is not frequent, the contact action may be insensitive or ineffective. This hidden danger may directly lead to the failure to timely alarm or lock when the pressure in the SF6 switch drops to the alarm or lock value due to gas leakage, resulting in a major accident. Therefore, the SF6 gas density relay should be checked regularly. According to Article 13.1.6 of the "25 Key Requirements of the National Energy Administration on Preventing power Production Accidents" (National Energy Safety (2014) No. 161), the connection between the sulfur hexafluoride density relay and the switchgear body should meet the requirements of not disassembling the check density relay.

The 220kV boost station of Huatian (Zhangping) Energy Co., Ltd. involved in the project uses outdoor column transformer produced by Shanghai MWB, with a total of 18 density relays in 6 intervals. Due to the early age of the equipment, there was no reliable and convenient check density relay interface, which could not meet the requirements of check density relays in operation without disassembly. Therefore, it is necessary to install a total of 18 point density relays at 6 intervals without disassembling the SF6 density relay three-way valve device.

03. Project implementation

In this scheme, the interface is updated and reformed, and the three-way valve device of SF6 density relay for online verification without disassembly is installed, and the connection link is adapted according to the interface characteristics of the product, so as to meet the requirements of density verification relay without disassembly in operation. Because the density relay works outdoors, if there is no rain cover for the density relay, a rain cover device is added to solve the impact of external rain and dust on the density relay, improve the working environment of the density relay, and extend the service life of the density relay. After the installation and renovation is completed, calibration personnel can be arranged to carry out on-site testing and calibration of all SF6 density relays according to the requirements of the power plant, and submit the calibration report.

The added non-disassembly on-line check SF6 density relay three-way valve device includes a density relay check self-sealing interface, a check interface protective plug cap, a valve operating switch and an interface corresponding to the switch body, and an integrated pin three-way valve device for mounting the density relay interface. The three-way valve device (aluminum alloy material, brass material and 316 stainless steel material can be selected by the user), through the installation of non-disassembly check three-way valve device so that it can be easily calibrated in operation without disassembling SF6 density relay (indicating value calibration, alarm contact action value calibration, locking contact action calibration). In order to meet the function of verifying the density relay without power failure and without disassembling the SF6 density table, it can also meet the operation of micro-water and decomposition detection and gas filling inside the gas equipment.

Formulation of specific construction plan: Weavers Technical Service Engineering Department arranges fully qualified professional and technical personnel and Fu

Relevant personnel of Jianlongyan Power plant go to the site to collect data of the manufacturers of the production equipment such as transformer, circuit breaker equipment model and density table that need to be reformed, the number that needs to be reformed and the specifications and dimensions of each interface of the three-way valve device that needs to be installed, and map the interface of the on-site calibration and renovation equipment and issue the implementation plan of relevant technical transformation. Surveying and mapping mainly surveys and collects information such as SF6 density relay interface, column type circuit breaker device body interface and installed three-way valve length, size and specifications, and verifies the company's system database information before issuing relevant drawings, which are processed and produced after being confirmed and signed by the user, and then on-site installation and other work are carried out during the planned power outage maintenance period of the power plant.

04 Technical Performance

SF6 density relay no disassembly check three-way valve is installed with a combination valve with a breaking device through the SF6 density relay interface on the basis of not changing any of the original structure of the switch. The valve is provided with a connector for the original SF6 density relay interface, a SF6 density relay connector, a breaking device and a connector for connection with a special SF6 density relay calibrator. After the connection is made according to the design requirements, the gas path of SF6 density relay and the gas path of switch body can be realized by rotating the breaking device. When it is necessary to verify the SF6 density relay, it is necessary to rotate the breaking device on the valve body to the closed state, and then complete the connection between the calibrator interface and the calibration interface reserved on the valve body, so as to realize the calibration of SF6 density relay, which can greatly save the precious time of maintenance personnel. It can also greatly reduce the risk of SF6 gas leakage due to regular verification disassembly.

Functional features:

1. Convenient for SF6 high voltage switch density relay calibration, inflation, water, decomposition, purity measurement;

2. The manual valve operation is simple and flexible, and the status mark is clear;

3. The valve body is made of stainless steel or brass or reinforced aluminum, user optional;

4. The pressure inside the valve body is > 0.1MPa high pure nitrogen.

5. Compatible with various specifications of switching interfaces at home and abroad;

6. Ambient temperature: -40 ~ +80℃.

Main indicators:

1. Pressure level: PN68;

2. Sealing performance (leak test) : absolute leakage rate ≤1×10-9Pa.m3/s;

3. Sealing form: metal hard seal and O-ring seal (according to different switch objects);

4. Impact resistance :600m/s2, impact time: 11ms;

5. Corrosion environment test: IEC60068-2-11 standard test; Service life: 100000 times (number of switching valve);

6. Material structure: brass, imported reinforced aluminum or imported 316 (material optional);

7. Structure: ball valve structure, spool for metal seal (anti-oxidation, corrosion resistance);

8. Three-way valve material: All kinds of materials have oxidation resistance and corrosion resistance.

9. Leakage test: leakage rate <10-15MPa.m3/s;

10. Anti-riot pressure test: under 4 times PN, the valve is normal;

11. Impact vibration test: after 10000 times of impact, the leakage value is less than 1×10-8mbar*l/s;

12. Rotation test: Install rotation test for the thread 600 times, without any change in the thread;

13. Connected trachea for related tests, test content;

14. Protection level: IP68.

05, follow the technical standards

l Comply with national or industry technical standards:

l SF6 General specification for calibration of gas density relays and density meters JB/T10549.

l Pressure type sulfur hexafluoride gas density controller GB/T22065.

l Verification regulation of pressure type sulfur hexafluoride gas density controller JJG1073.

l General pressure gauge GB/T1226.

l Electric contact pressure gauge JB/T9273.

l Electrical relay GB/T11287 (idt IEC60255).

l Enclosure protection grade GB4208 (eqv IEC60592).

l Electromagnetic compatibility GB/T17626 (idt IEC60592).

l Basic test methods for relays and devices GB/T7261.

l Industrial automation instrument JB/T9253.

l Technical conditions for the packaging and transportation of relays and devices JB/T7828.

l Electrical installation engineering high voltage electrical equipment construction and acceptance code.

l Sulfur hexafluoride electrical equipment operation, testing and maintenance personnel safety protection rules DL/T639.

Code DL/T603 for Operation and Maintenance of gas insulated metal enclosed switchgear.

The applicable national standards and industry standards are as follows (if there is a newer version, it will be implemented in accordance with the new standard) :

01. Verification Procedure for sulfur hexafluoride Gas Density Relays DL/T 259-2012

02. "Sulfur hexafluoride in electrical equipment gas management and detection guidelines" GB/T 8905-2012

03. Code for Design of Power Supply and Distribution System GB50052-2009

04. "High voltage Test equipment General Technology Part 6" DL/T846.6-2004

05. "High Voltage Switchgear Anti-accident Technical Measures" Guoxinfa [1999]72

06. "25 Key Requirements for Preventing Power Production Accidents" National Energy Safety [2014] No. 161 and State Grid "18 Major Anti-accident Measures of State Grid Corporation"

07. GB11022 "High voltage Switchgear general technical Conditions"

08. DL/T 596-2005 "Electrical Equipment Preventive Test Code"

09. GB1984-2003 "High voltage AC Circuit Breaker"

10. GB/T8905-1989 "Guidelines for Gas Management and Monitoring in sulfur Hexafluoride Electrical Equipment"

11. State Grid "Measures to Prevent AC High-voltage Switchgear Accidents"

12. State Grid "110 (66) KV-500KV AC high voltage Circuit breaker maintenance Code"

13. State Grid "High Voltage Switchgear Operation Code"

06, installation and commissioning progress guarantee measures

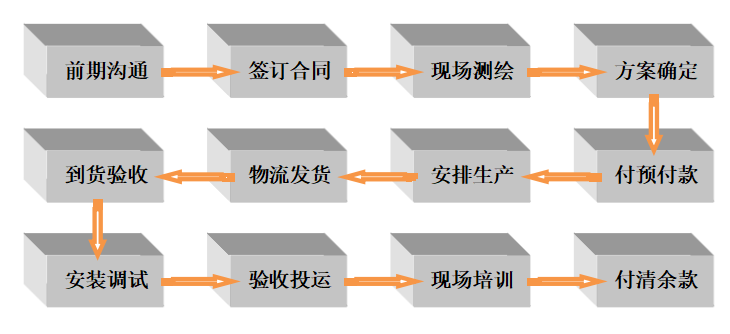

1) Program implementation process

WINFOSS company in order to provide customers with high quality, reliable products and convenient, worry free service for the purpose of the development of the following project implementation process:

WINFOSS company in order to provide customers with high quality, reliable products and convenient, worry free service for the purpose of the development of the following project implementation process:

2) Product delivery date

SF6 density relay valve control tee joint quantity is less than 20 sets of products, according to the contract signed within 35 days of delivery. If the demander's project is urgent, our company can prioritize production and delivery within 25 days after signing the contract. 20-100 sets of products, the delivery time will increase by 5 days air tightness inspection time.

3) Product installation

04.2.1 Installation preparations

4.2.1.1 The relevant technical personnel of the company and the person in charge of the site construction project will survey the construction site, determine the site operation environment and the type and size of the corresponding switch interface, etc., and make necessary preparations for the problems that may occur in the site installation.

4.2.1.2 Before installation, the construction preparation meeting is held to make each department clear the construction work content, progress and specific implementation methods, and do all the preparatory work before construction.

04.2.3 Installation work arrangement

l Weavers service engineer is responsible for the inventory of equipment, tools, etc., the handling of items, and the preparation of accessories required on site.

l Weavers service engineers are responsible for communicating with users to develop site implementation plans, installation plans and safety measures.

l The user is responsible for issuing work tickets, providing traffic vehicles, on-site supervision, construction power supply, scheme determination, etc.

l All original density relays are leak detected, disassembled, protected and marked by Weavers service engineers.

l Weavers Service engineer is responsible for all installation of the three-way valve, and on-site leak detection and marking after installation.

l Weavers service engineers are responsible for on-site training, equipment and user materials handover, acceptance and formal operation.

EN

EN

上一条:

上一条:

沪公网安备31011802003762

沪公网安备31011802003762