专注于SF6气体检测的专业化

Application of SF6 concentration on-line monitorin

GB/T8905-1996 "Guidelines for Gas Management and Detection in sulfur hexafluoride Electrical Equipment" and DL 408— 1991 "Electrical Safety Work Regulations" (electrical parts of power plants and substations) and "Eighteen Major Anti-accident Measures of the State Grid Company" specifically stipulate that the distribution unit room equipped with SF6 equipment must ensure that the SF6 gas concentration is less than 1000ppm, in addition to the installation of strong ventilation devices, The oxygen meter and SF6 gas concentration detector must be installed.

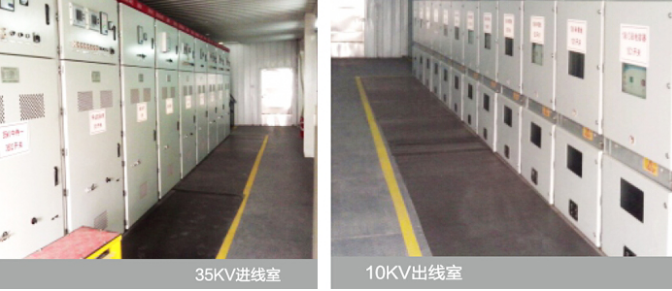

Wevers Liaocheng Linqing Daxinzhuang 35KV substationSF6Concentration on-line monitoring system(winfoss -S1Application advantages:

lMulti-master mode work, without the need for the distributor in the traditional measurement and control network, any monitor in the system can send information to other monitors in the network independently, regardless of master and slave.

lUsing non-destructive bus arbitration technology, when multiple monitors send data, the monitor with a higher priority can continue to transmit data without being affected, improving the data loss and even network paralysis caused by network data conflicts.

lStrict error detection and definition, any monitor in the system abnormal does not affect the work of other equipment.

l Support distributed CAN bus technology, the system has the following advantages:

1. Accurate data sampling and low bit error rate;

2. The system structure is clear, the installation is simple, and the maintenance cost can be reduced.

3. Large system capacity,To solve the user's concern of flexible extension of the monitor in the later stage;

(4) Strong anti-interference, improve the stability and reliability of the system.

l32-bit DSP (digital signal processing) technical features:

l32-bit data parallel processing, leakage alarm response is rapid;

lBuilt-in multiple 16-bit resolution A/D converters improve the quantization accuracy of the sampled data;

l Built-in multiple D/A converters can easily realize the intelligent control of field equipment;

l Mass storage, can store at least 15 years of historical detection data;

l The 10.4-inch LCD display interface is the largest display interface currently used in the field industrial control system, and all monitoring data can be displayed on the same screen at the same time, which increases the beauty of the product and is more convenient for users to visually view the monitoring data, and the operation is simple and convenient. It overcomes the deficiency that some data in the 4-8 inch interface of the traditional industrial control system must enter the sub-interface to browse and operate.

l The system adopts a full-chip chip with a modular design of partitions to improve system integration and reliability while reducing product power consumption.

l The SF6 infrared sensor using the Swiss original infrared spectrum principle sensing and detection technology, the main advantages are as follows:

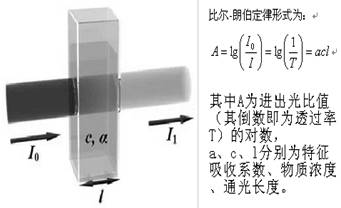

non-dispersive infrared absorption (NDIR)It is a spectral gas detection method based on gas absorption theory. Its manifestations are as follows:Infrared light source emits infraredAfter the radiation is absorbed by a certain concentration of gas to be measured, the intensity of the light at a specific wavelength (SF6 corresponds to 10.6um) will change correspondingly with the concentration of the gas, and the change law can be described by Beer-Lambert absorption law. Therefore, the gas concentration can be calculated according to the change of light intensity.

l The leakage concentration of SF6 directly determines the resistance distribution on the sampling circuit, and the sampling current changes, and the response is rapid. It overcomes the shortcomings of low detection accuracy and slow sampling speed caused by the need to detect new substances in the early catalytic combustion technology.

l The resistance change of the detection layer determines the strength of the output current, which is easy to quantify and not susceptible to environmental temperature and humidity interference. It overcomes the influence of ambient temperature and humidity when the catalytic combustion technology must be heated to 500-600℃.

EN

EN

上一条:

上一条:

沪公网安备31011802003762

沪公网安备31011802003762