专注于SF6气体检测的专业化

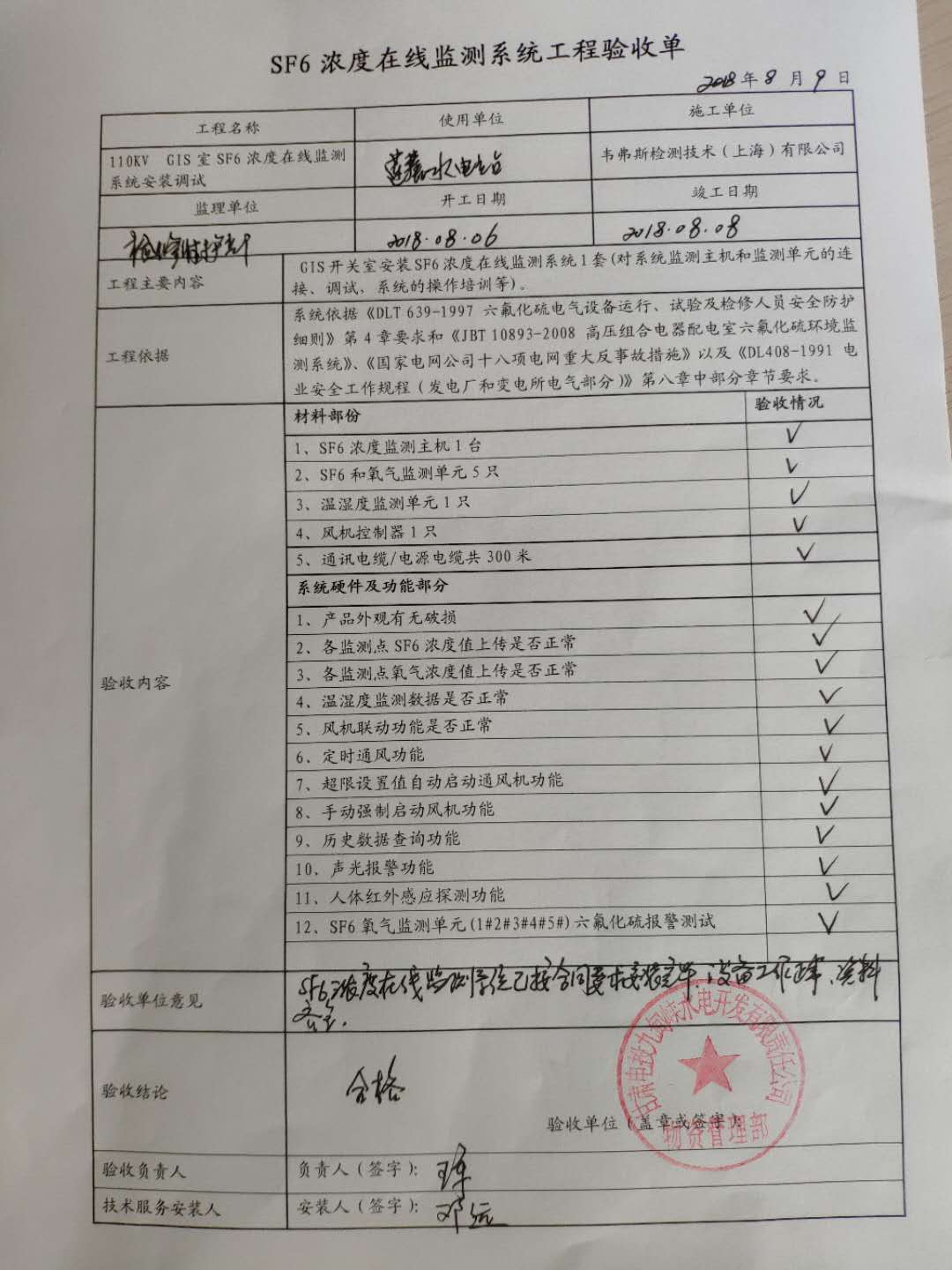

SF6 concentration online monitoring system project

SF6 concentration online monitoring system project of Lianlu Hydropower Station

Gansu Power Investment Tao River Electric Development Co., Ltd. is mainly engaged in the development, operation, production and sales of hydroelectric power generation projects; Hydropower equipment maintenance, energy-saving technology development. Taohe Company is a wholly-owned subsidiary of Gansu Power Investment Energy Development Co., LTD. The company has five cascade power stations: Lianlu Hydropower Station (66MW), Xancheng Hydropower Station (37.5MW), Geely Hydropower Station (20MW), Haidian Gorge Hydropower Station (60MW) and Sanjia Hydropower Station (31.5MW), with a total installed capacity of 215MW.

In September 2018, the original SF6 concentration online monitoring system of 110KV GIS switch room of Lianlu Hydropower Station was originally applied to the products of a company in Jiangsu and Zhejiang. The product SF6 gas collection adopts pipeline pump suction structure, and the gas pipe adopts ordinary polytetrafluoroethylene pipe, which has been affected by environmental factors for a period of time, resulting in pipeline distortion and torsion. Secondly, it is pumped for long distance transportation, and the pump absorption architecture adopts a single actual state that destroys the field environment gas collection. The original system adopts the domestic acoustic wave method principle sensor for the analysis of SF6 gas, and the sensor can also detect the on-site paint construction or decomposition, and the cable surface material decomposition. Therefore, the pumping type can not accurately reflect the true level of each leakage point.

Our company adopts the diffused architecture than the pumping architecture has some advantages, as follows:

1. The distributed architecture is on-site distributed real-time detection, and there is no physical interference conditions such as sampling pump machinery or pipelines in the pumping architecture, which can most truly reflect and warn the SF6 standard and oxygen level of each on-site (especially the hypoxia situation once it is pumped for long distance transportation, it will destroy the actual state of the site). Therefore, the pumping type can not accurately reflect the true level of each leakage point.

2. Diffusion Because each leakage point is equipped with an SF6 infrared sensor and an oxygen sensor, the sampling at each point is independent of each other, and both are in-situ analog acquisition and digital conversion sampling after direct contact. There is no secondary sampling analysis chamber in the pumping architecture, and the detection accuracy is not affected by the mixing of residual gas in the pipeline and analysis chamber. In addition, a substation in the pumping architecture has only one infrared SF6 sensor and one oxygen sensor, and once the sensor fails or is poor, all monitoring points of the entire system will fail.

3. The diffused type is on-site real-time detection, there is no long pumping collection pipeline, and the time difference caused by the switch and analysis of the solenoid valve one by one, and the real-time is the best. The alarm response speed is fast, and there is no time delay caused by the solenoid valve switching analysis. It is emphasized from the above industry standard 7.1.3 that the pipeline in the pumped architecture should not exceed 30 meters, but in practical applications, even medium-sized 110KV substations, due to the bending specification of the cable trench laying, more than 30 meters is very common. And the clause also emphasizes: if multiple detection sampling points are configured, the sampling time of each sampling point should not exceed 5 minutes, and the total sampling period should not exceed 1 hour, which indicates that the real-time performance is not good, and there are many projects with more than 12 monitoring points in practical application, so there are great application limitations.

4. Because there is no mechanical structure of the solenoid valve, and sampling suction pump, these two parts are due to the need to run sampling every moment for years, so there is a risk of mechanical wear in about 1 year, or even damage. Due to the complex mechanical structure, the maintenance work is very troublesome and the maintenance cost is very high.

5. Diffusion also does not exist because the pump type lays a large number of tetrafluorotube from the analysis host to the site monitoring point, the tetrafluorotube is subject to subsequent construction or maintenance and other factors that lead to cable extrusion, and the situation that the gas is not extracted often occurs, and the user can not check or check themselves is very troublesome, and the workload is large.

EN

EN

上一条:

上一条:

沪公网安备31011802003762

沪公网安备31011802003762