专注于SF6气体检测的专业化

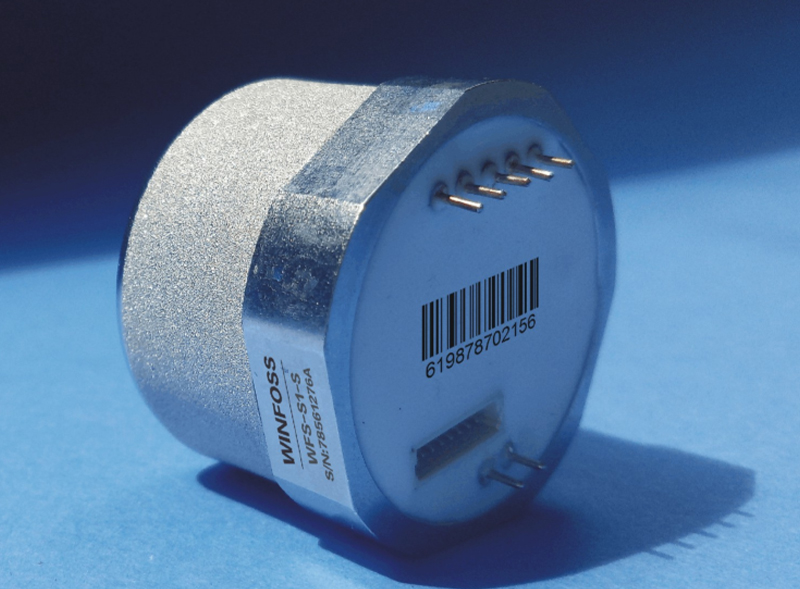

SF6 Gas Density Relay (Winfoss-D6)

SF6 gas density relay

Supported platform: Windows/Linux/Unlix

Software size: 10M

Brand: WINFOSS

Model: WINFOSS-D6

Accuracy level: 1.5.

Measuring range: -0.1 ~ 0.9Mpa.

Sealing performance: ≤10-9 Pa·m3/s.

When the rated pressure is greater than 0.5Mpa, the ambient temperature ranges from -25 ° C to +60 ° C.

When the rated pressure is ≤0.4Mpa, the ambient temperature ranges from -40 ° C to +60 ° C.

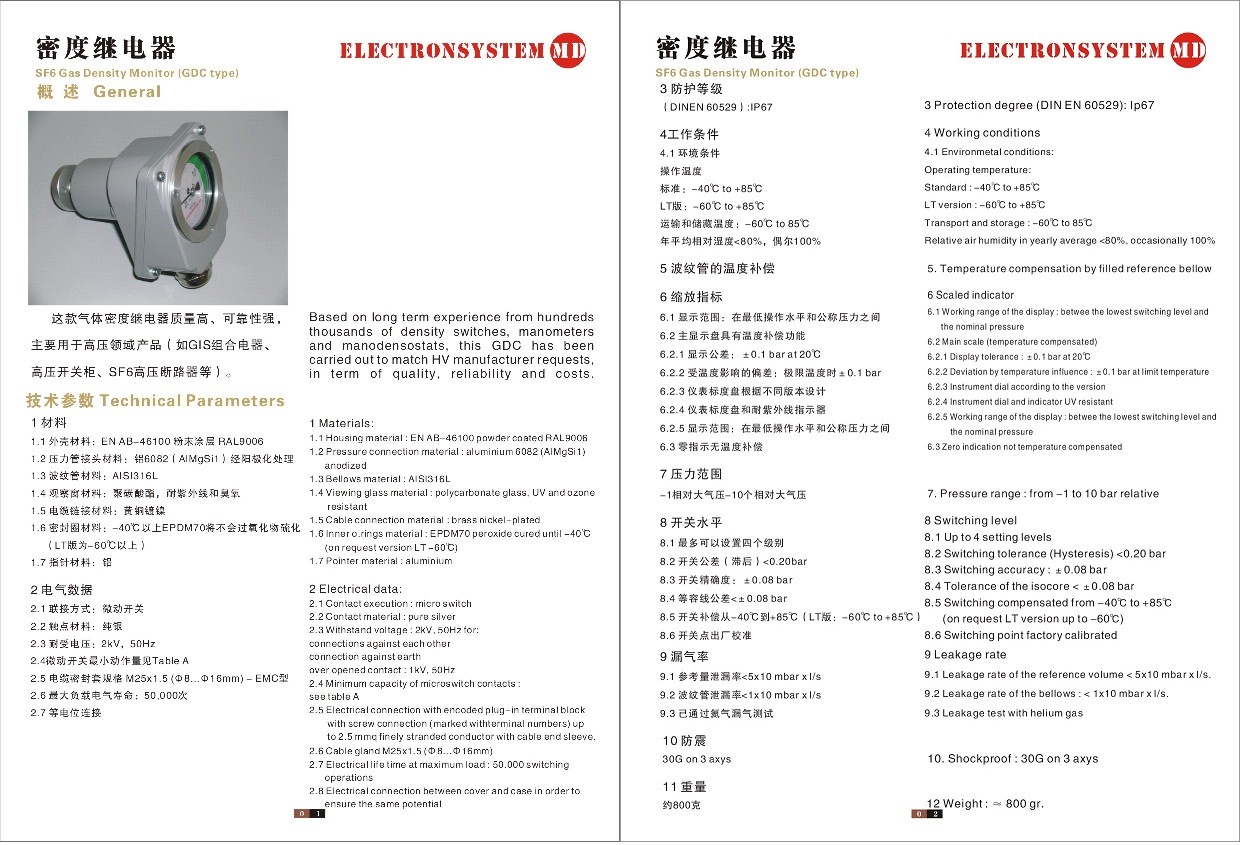

The SF6 gas density relay (WINFOSS-D6) is mainly used to monitor the density of SF6 gas in sealed containers. It is widely used in high-voltage electrical equipment with SF6 gas as the insulating medium, and is suitable for outdoor harsh working environment. The density relay has two or three sets of contacts (defined according to different requirements), which can emit overpressure, alarm and lock control signals, with an indication display. Density relays are filled with silicone oil to improve seismic and shock resistance.

SF6Gas density relay(WINFOSS-D6)

Precision manufacturing, parameters and interface specifications can be customized; Suitable for all kinds of switch factory interface installation and application at home and abroad!

summarize

The SF6 gas density relay (WINFOSS-D6) is mainly used to monitor the density of SF6 gas in sealed containers. It is widely used in high-voltage electrical equipment with SF6 gas as the insulating medium, and is suitable for outdoor harsh working environment. The density relay has two or three sets of contacts (defined according to different requirements), which can emit overpressure, alarm and lock control signals, with an indication display. Density relays are filled with silicone oil to improve seismic and shock resistance.

In addition, it can also be customized remote transmission SF6 density relay (WINFOSS-GDC-R), which integrates precision pressure sensor and digital temperature sensor, adopts high-performance microprocessor to collect pressure and temperature signals, calculates the standard pressure value at 20℃ by empirical formula, and transmits to the upper computer through the data bus. In addition, it can also be connected to the monitoring system of the control room through the 4-20mA standard signal, especially suitable for centralized monitoring of multiple SF6 gas chambers, which can transmit the density information in the entire monitoring area to the control room, use the microcomputer to display and store data in real time, and can also describe and print the daily, monthly and annual density change curves.

Principle introduction

Among them, the remote SF6 density relay consists of two parts, one is the pointer indication and control part of the traditional density relay, and the other is the intelligent monitoring and communication part to meet the needs of online monitoring.

l Principle of indication and control:

The SF6 gas density value indicated by the pointer on the SF6 gas density relay dial is expressed by the pressure of SF6 gas after temperature compensation, that is, the standard pressure value at 20℃. SF6 density relay works under the rated pressure. When the ambient temperature changes, the pressure of SF6 gas also changes. The temperature compensation unit inside the density relay corrects the changed pressure so that its pressure indication value remains unchanged. When SF6 gas leaks, the pressure will drop, and when it drops to the alarm setting value, a pair of contacts of the density relay will output an alarm signal, at which time the user is required to air the equipment. If the pressure continues to drop, when it drops to the locking setting value, a pair of contacts of the density relay will output a locking signal, so that the control system of the equipment will be locked, so as to realize the safe operation and protection of the electrical equipment.

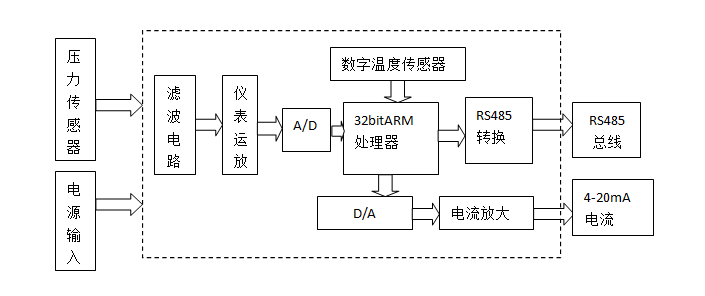

l Intelligent monitoring and communication principles

The intelligent module in the density relay mainly monitors the pressure sensor signal, through filtering and operation amplifier, and then through high-precision A/D conversion to obtain the digital signal, and then by the high-performance processor combined with the temperature signal to convert the density, can use D/A to convert the analog signal, and then converted into 4-20mA current signal output, another way using RS485 bus output.

While these solutions can meet the need to provide security protection for equipment, they have not been able to meet the emergency or more complex security needs of some non-professionals. In particular, there is a lack of more effective tools to solve problems in a timely and professional manner, such as if you have at least one or more of the following problems that have been unresolved for a long time.

Technical parameter

l Measuring range: -0.1 ~ 0.9Mpa.

l Accuracy level: 1.5.

l Smart module power supply: DC 12 ~ 30V Power consumption <30mA.

l Smart module output mode: RS485 and 4-20mA.

l Intelligent module communication protocol: IEC60870-5-103 or customized according to customer requirements.

l Seismic performance: 20m/s2.

l Impact resistance: 300m/s2.

l Insulation resistance: the insulation resistance between the leads, the lead and the housing is > 200MΩ .

l Enclosure protection class: IP65.

l Sealing performance: ≤ 10-9 Pa· m3/s.

l Contact capacity: AC/DC 250V, 30VA/W.

l Working environment: relative humidity ≤ 95%RH.

l When the rated pressure is greater than 0.5Mpa, the ambient temperature is -25 ° C to +60 ° C.

l Rated pressure ≤ At 0.4Mpa, the ambient temperature ranges from -40 ° C to +60 ° C.

l Withstand voltage: 2KV,50Hz.

l Electrical life: 50000 times.

l Reference leakage rate <5X10mbar xl/s.

peculiarity

l Based on the traditional density relay, the built-in intelligent module not only retains the advantages of mechanical density relay reliability and stability, but also meets the needs of SF6 density online monitoring.

l Full stainless steel shell, good waterproof and anti-corrosion performance, and beautiful appearance.

l Temperature sensing element adopts imported material, stable performance and good consistency.

l Control one.

l Filled with silicone oil, with vibration resistance, impact resistance.

l Contact device is magnetically assisted, high performance electrical contact.

l Complete specifications, can be customized according to user contact requirements.

Service guarantee

l Provide on-site training guidance and carry out on-site demonstration operation.

l Provide detailed instructions and user guidance in Chinese.

l One year warranty, lifelong spare parts support and maintenance.

l Hotline 365 days to answer the user's consultation.

EN

EN

上一条:

上一条:

沪公网安备31011802003762

沪公网安备31011802003762