专注于SF6气体检测的专业化

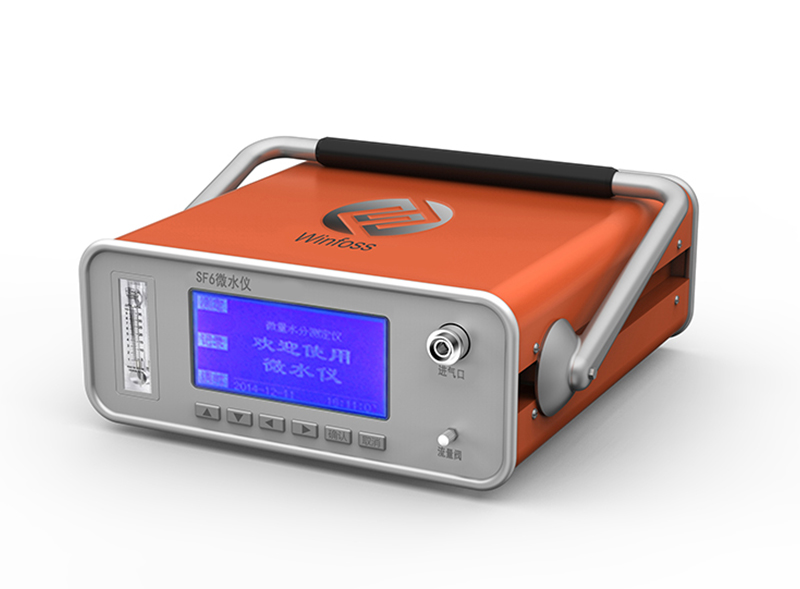

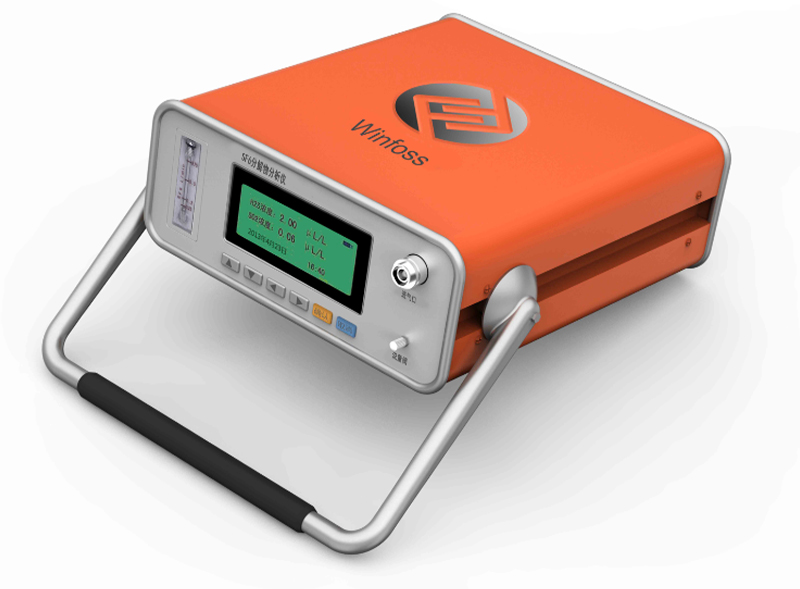

SF6 Microwater Density On-line Monitoring Device (Winfoss-S6)

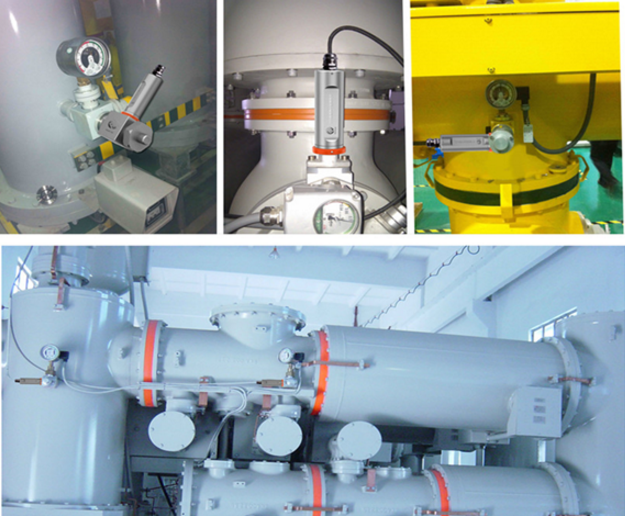

SF6 density micro-water on-line monitoring system

Supported platform: Windows/Linux/Unlix

Software size: 10M

Brand: WINFOSS

Model: Winfoss-S6

Pressure range: 0.000MPa ~ 1.000Mpa

Pressure accuracy: 1 level; Resolution: 0.001Mpa

Dew point measurement: -80℃ ~ 20℃

Dew point accuracy: ±2℃; Resolution: 0.1℃

Temperature measurement: -30℃ ~ 85℃

The SF6 Micro-water density online monitoring device (Winfoss-S6) makes it more convenient for users to access and understand the operating status of each substation anytime and anywhere. Maintenance personnel can clearly know what they need and how to do it. At the heart of all this technology is the DRYCAP® based micro-water measurement analysis algorithm and the digital SF6 gas density monitoring technology. The expert diagnosis system is formed by combining digital processing technology (DSP) and real-time database technology. It ensures that the change of dynamic digital pressure and micro-water monitoring data can accurately reflect the deterioration trend of gas quality inside the switch, and provide a scientific basis for users to provide state preventive maintenance.

SF6 Microwater Density On-line Monitoring Device (Winfoss-S6)

Original imported sensor, precision measurement, long life; High sealing performance, zero leakage, effectively protect the safety of high voltage electrical equipment!

summarize

According to "Q_GDW 534-2010 Substation equipment Online monitoring system Technical Guidelines", "DLT 1054-2007 High voltage electrical Equipment insulation technical supervision regulations", "QGDW 172-2008 SF6 High voltage Circuit Breaker condition maintenance Guidelines", "DLT 846.5-2004 General Technical Conditions for high voltage test equipment - Part 5: sulfur hexafluoride trace moisture meter.

The SF6 Micro-water density Online monitoring device (Winfoss-S6) makes it more convenient for users to access and understand the operating status of each substation anytime and anywhere. Maintenance personnel can clearly know what they need and how to do it. The core attribution of all these technological achievements is based on DRYCAP® Detection technology basic micro-water measurement analysis algorithm and digital SF6 gas density monitoring technology. The expert diagnosis system is formed by combining digital processing technology (DSP) and real-time database technology. It ensures that the change of dynamic digital pressure and micro-water monitoring data can reflect the deterioration trend of gas quality inside the switch, and provides a scientific basis for users to provide state preventive maintenance.

Feature

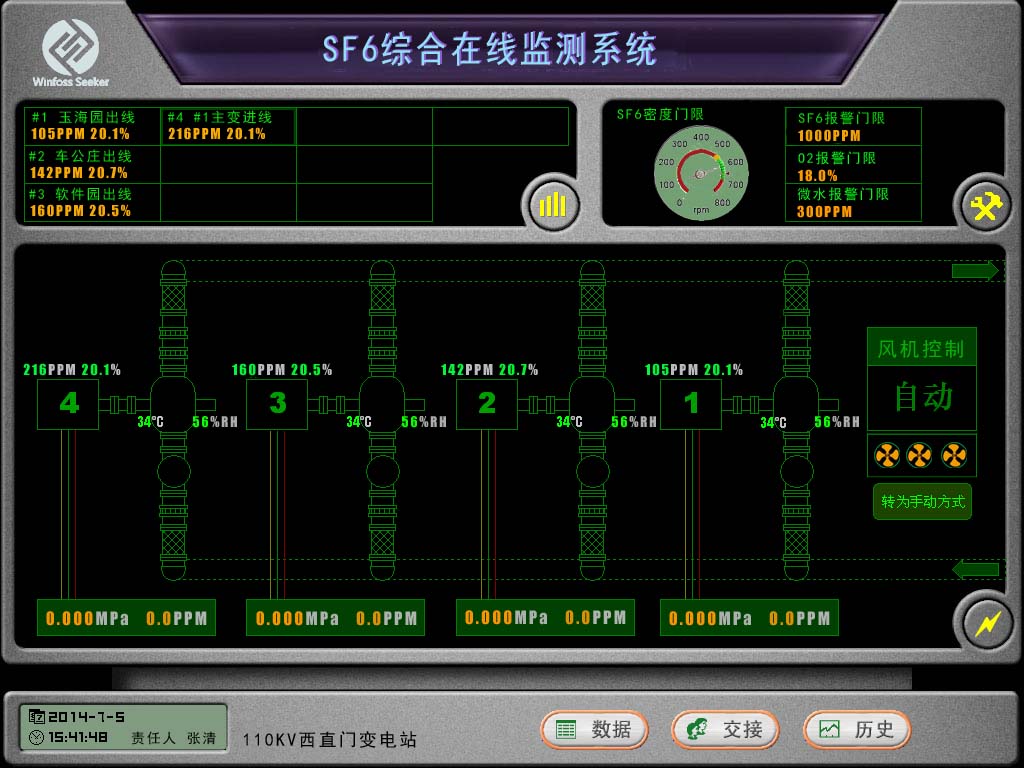

l Realize the online monitoring function of SF6 gas moisture and density in the detected gas chamber, and centrally display the monitoring unit number, standard pressure (20℃), moisture value (ppm), current pressure, current temperature, dew point value, density alarm value and lock value on the server.

l The monitoring quantity exceeds the threshold alarm function.

l Monitoring data storage function.

l Density micro-water monitoring point arbitrary expansion function.

l Alarm/lock value self-adjustment function.

l Automatically plot the trend of state changes.

l Supports remote data transmission.

l User rights management function.

l Data transmission encryption function.

l The system complies with the IEC61850 communication protocol, and can be connected with other equipment to meet the communication requirements of intelligent digital substation of power system.

l Compatible with all domestic and foreign switch interface access.

peculiarity

l Realize the online monitoring function of SF6 gas moisture and density in the detected gas chamber, and display the monitoring unit number, standard pressure (20℃), moisture value (ppm), current pressure, current temperature, dew point value, density alarm value, density lock value and other parameters on the server.

l Can be used for indoor and outdoor real-time monitoring.

l Storage function for monitoring data overload alarms.

l Density micro-water monitoring point arbitrary expansion function.

l Alarm/lock value self-adjustment function.

l Automatically plot the trend of state changes.

l Supports remote data transmission.

l User rights management function.

l Data transmission encryption function.

Monitoring interface

System parameter

Serial number | ginseng The number item Orders, | ginseng The number value |

one | Pressure range | 0.000MPa to 1.000 Mpa |

2 | Pressure accuracy | Lv.1; Resolution: 0.001Mpa |

3 | Dew point measurement | -80℃ ~ 20℃ |

4 | Dew point accuracy | ±2° C; Resolution:0.1℃ |

5 | Temperature measurement | -30℃ to 85℃ |

6 | Temperature accuracy | 1 ° C; Resolution: 0.1℃ |

7 | Factory rated pressure value | 0.600Mpa, can be preset according to requirements |

8 | Factory pressure alarm threshold | 0.520MPa, the lifting threshold is 0.530MPa; Can set |

9 | Factory pressure locking threshold | 0.500MPa, the lifting threshold is 0.510MPa; Can set |

10 | Factory water alarm threshold | 300ppm, preset on request |

11 | Communication interface | CAN or RS485 (Baud rate 2400bps) |

twelve | Working power supply | AC 220V ± 25% |

13 | Contact capacity of each relay | 5A/250VAC, 5A/30VDC |

fourteen | Class of protection | IP64 |

15 | Working environment | Indoors or outdoors |

16 | Seismic cracking | Lv.8. Dynamic peak acceleration: 0.25g |

17 | Operating temperature | -35℃ - +95℃ |

System configuration

l SF6 micro water density monitoring server (including monitoring software).

l SF6 Density micro-water monitoring unit (depending on the number of monitoring chambers).

l SF6 density monitoring unit (depending on the number of monitoring chambers).

l Tee adapter kit (depending on number of monitors).

l Data collector (based on actual requirements).

l Flame-retardant cable (depending on actual demand).

l 1 user manual.

l Factory test report and other user data 1 set.

Service guarantee

l Provide on-site installation, commissioning and training guidance, and carry out on-site demonstration operation.

l Provide detailed instructions and user guidance in Chinese.

l One year warranty, lifelong spare parts support and maintenance.

l Hotline 365 days to answer the user's consultation.

EN

EN

上一条:

上一条:

沪公网安备31011802003762

沪公网安备31011802003762